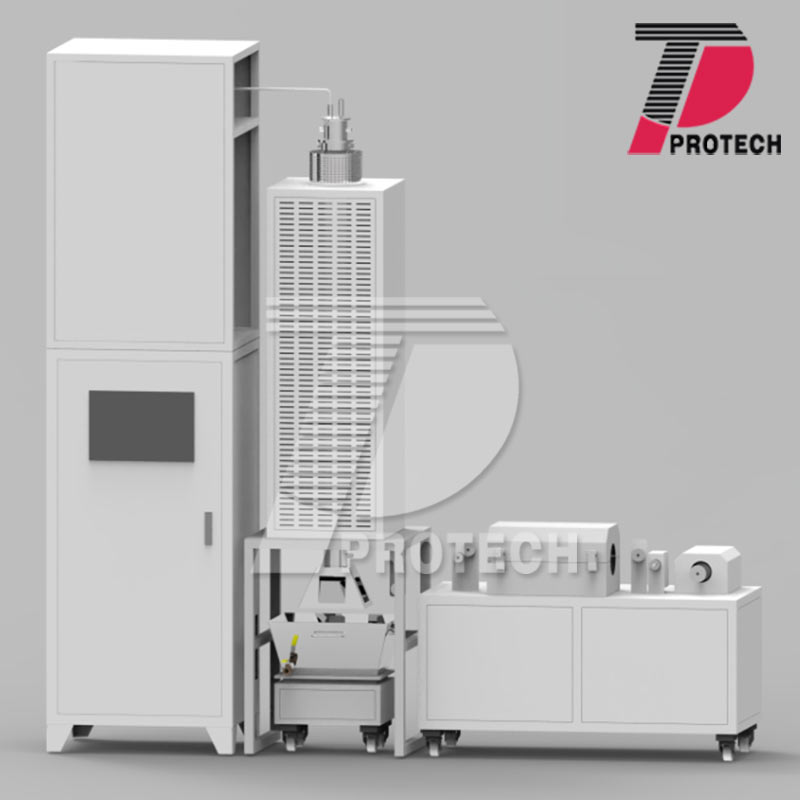

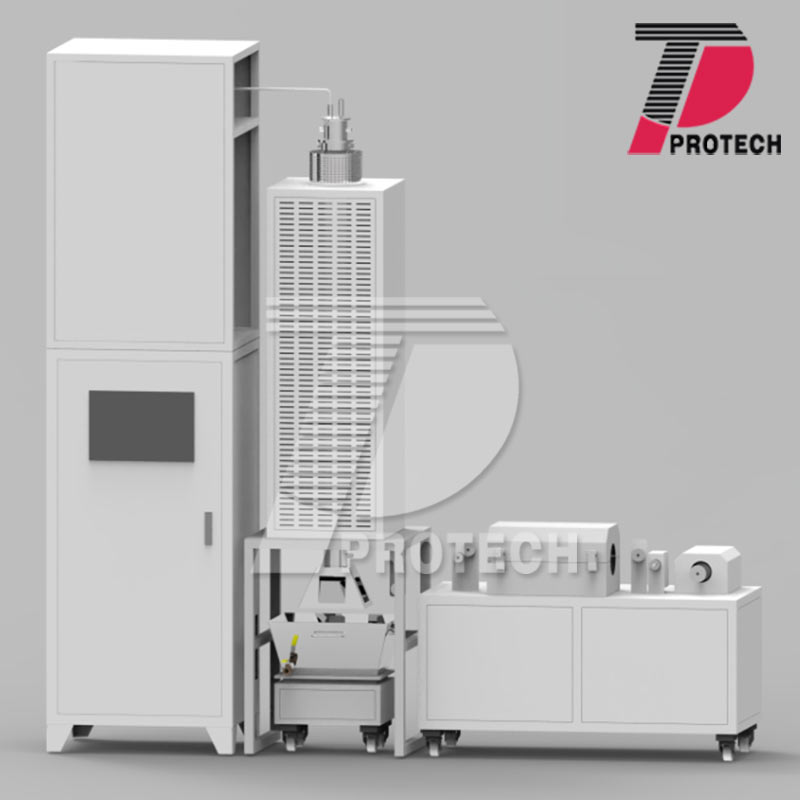

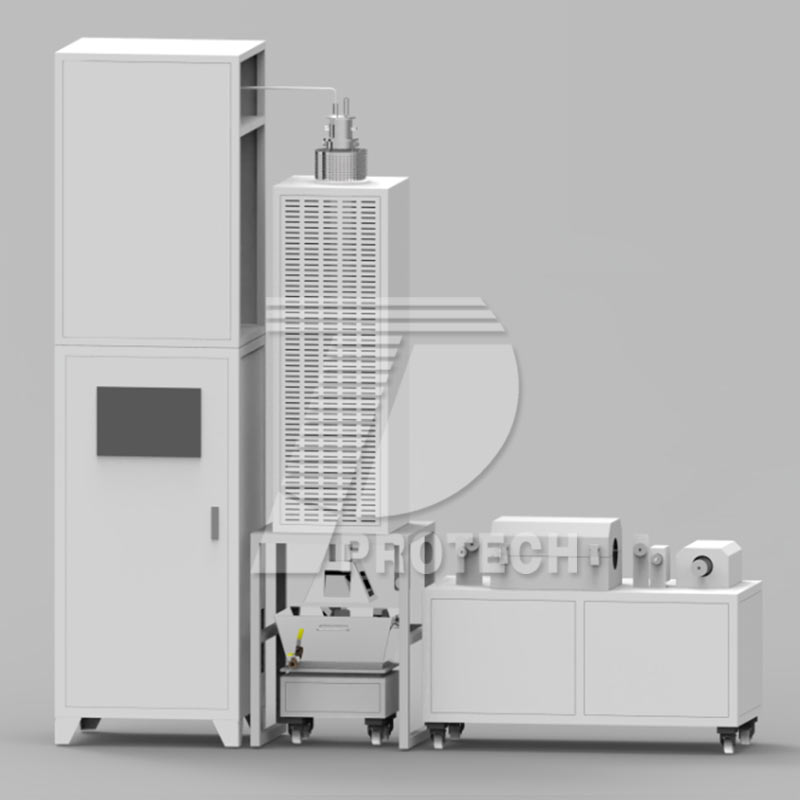

model:PT-T1400V

Special furnace for nanowire growth

Application: Protech company developed special furnace for continuous carbon nanotube and nanowire growth. It consists of airflow control system, liquid injection system, multi-stage temperature controllable multi-zone growth system, water cooling system, carbon nanowire or membrane collection system, infrared drying system, etc. The maximum temperature of the growth furnace is 1400°C, which can be continuously adjusted between 0-1400°C. The heat field is distributed vertically, and the temperature is controlled at two points. The top of the equipment is equipped with a liquid injection port and a flow guide. This carbon nanotube or film CVD equipment can realize the characteristics of continuous growth and uninterrupted growth.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Main featureD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Protech company developed special furnace for continuous carbon nanotube and nanowire growth. It consists of airflow control system, liquid injection system, multi-stage temperature controllable multi-zone growth system, water cooling system, carbon nanowire or membrane collection system, infrared drying system, etc. The maximum temperature of the growth furnace is 1400°C, which can be continuously adjusted between 0-1400°C. The heat field is distributed vertically, and the temperature is controlled at two points. The top of the equipment is equipped with a liquid injection port and a flow guide. This carbon nanotube or film CVD equipment can realize the characteristics of continuous growth and uninterrupted growth.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Technical parameterD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Furnace structure:D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Double-layer shell structure with air cooling system, the shell surface temperature is less than 60℃D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· High-purity alumina is used as the furnace material, and the surface of the furnace is coated with a 1750 ℃ alumina coating imported from the United States, which can improve the heating efficiency (20%) and prolong the service time of the instrumentD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Furnace tube material: 99.8% high purity corundum tubeD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Furnace tube size: OD: 80mm x ID: 72mm X Length 1500mmD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Stainless Steel Vacuum Flange:D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

A set of stainless steel vacuum flanges are included in the instrument (with stainless steel needle valves and mechanical pressure gauges installed)D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Armored flange can be used to extend the thermocouple to the inlet to measure its temperatureD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Flange interface:D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

In order to obtain better vacuum degree faster, KF25 adapter can be usedD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

In order to better pass the gas, you can choose 1/4" stainless steel ferrule fittingsD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Flange interface can be customizedD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Heating element: High quality silicon carbide rodD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Operating temperature: · Continuous working temperature: 100-1400℃D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Maximum operating temperature: 1400℃D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Temperature Control System:D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

·Adopt PID method to adjust temperature, and can set 30 steps of heating and cooling programD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Use S-type thermocouple for temperature measurement and temperature controlD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Temperature control accuracy: +/-1 ℃D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Heating zone length: 700mm+400mmD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Length of constant temperature zone: 800mmD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

input power: Single phase, 220V AC, 50/60 HzD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Maximum power: 20KWD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Net weight: 200KGD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Quality certification and warranty period: CE certificationD54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

One year warranty (excluding furnace tube, heating element and seal wear parts)D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1. A water tank is added under the furnace tube, and the material is stainless steel. The water tank is designed with a trapezoidal structure, which is convenient for wire-discharging operation.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. In the water tank, there is a wire reel just below the furnace tube, which is driven by a motor. The wire reel is made of stainless steel, with a diameter of 40mm and a smooth surface.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. The lower end of the furnace tube is equipped with a bell mouth, the section is square, and a piece of plexiglass of 100x100mm (the visible area is 70x70mm) is inlaid on the two sides (the front and the right side) to facilitate the observation of the wire.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4. The height of the injection needle into the furnace can be adjusted, the material is stainless steel tube, the outer diameter is 3mm, and it can be connected with the thick tube.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5. The solution injection pump is at the same height as the furnace body, shortening the distance from the syringe to the injection port of the furnace body, and the injection pump and the injection port are connected with a hose.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

6. All gas pipelines are changed to stainless steel pipes.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

7. The temperature of the nozzle of the liquid injection port in the furnace can be measured, and the flange has been converted into an armored flange, which is convenient for temperature measurement.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8. The lower flange of the furnace tube adopts a water-cooled flange, and the water-cooled machine is provided by the customer.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

9. It is necessary to consider whether the heating furnace can be separated from the square tube below, which is convenient for forklift operation and easy to replace the furnace tube.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

10. The length of the electric control cabinet is lengthened by 200mm, which is convenient for the installation of the electric control part.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

11. The wire-receiving part is controlled by three stepping motors, and the speed is 0-100r/min, which is continuously adjustable.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

12. The thermocouple on the flange of the liquid injection port can adjust the distance of penetration, which is convenient for temperature measurement.D54Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac