model:PT-T1000

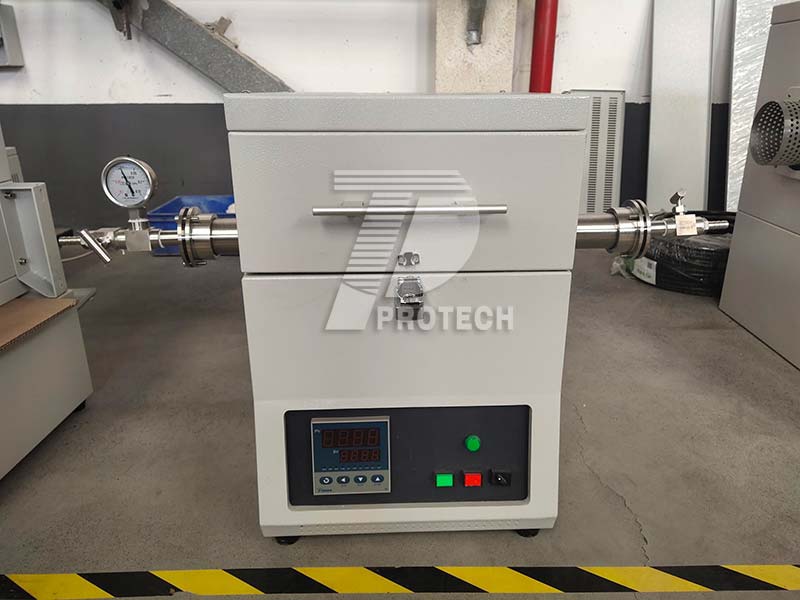

PT-T1000 Mini Tube Furnace

Application: PT-T1000 Mini Tube Furnace is mainly used for the preparation of rare earth, electronic lighting, crystal annealing, bio ceramics, electronic ceramics, special alloys, magnetic materials, precision casting, metal heat treatment and other industrial vacuum sintering, protective at

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Brief Introduction: BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

PT-T1000 Mini Tube Furnace is mainly used for the preparation of rare earth, electronic lighting, crystal annealing, bio ceramics, electronic ceramics, special alloys, magnetic materials, precision casting, metal heat treatment and other industrial vacuum sintering, protective atmosphere sintering, vacuum deposition, CVD experiments, material composition measurement occasions.Belongs to a type of tube furnace.BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The main features are as below:BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1. Great temperature uniformity.BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. Over temperature protection and alarm.BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. PID automatic control via SCR power control.BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Technical Parameter:

| Model |

PT-T1000 |

| Display |

LED |

| Max. Temperature |

1000℃ for short time |

| Continuous Working Temp. |

≤1000℃ |

| Heating Rate |

Suggestion 0~10℃/min(max. 20℃/min) |

| Temperature heating zone |

Single 200mm |

| Temperature Control Accuracy |

±1℃ |

| Tube Size |

Φ50× 600mm(Length) |

| Heating Element |

Fe-Cr-Al Alloy doped by Mo |

| Thermocouple |

K Type |

| Max. Power |

2.0 KW |

| Working Voltage |

AC 208V-240V single phase, 50 Hz (or according to your requirement) |

| Temperature Control |

PID automatic control via SCR power control |

| Heating curves |

30 steps programmable |

| Sealing flange |

Stainless Steel vacuum flange with valves and one mechanical pressure gauge |

| Furnace Pressure |

Max. 0.02Mpa |

| Chamber material |

Alumina Fiber |

| Warranty |

One year limited warranty (Consumable parts such as heating elements are not covered by the warranty) |

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BeHMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac