|

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Control PannelWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

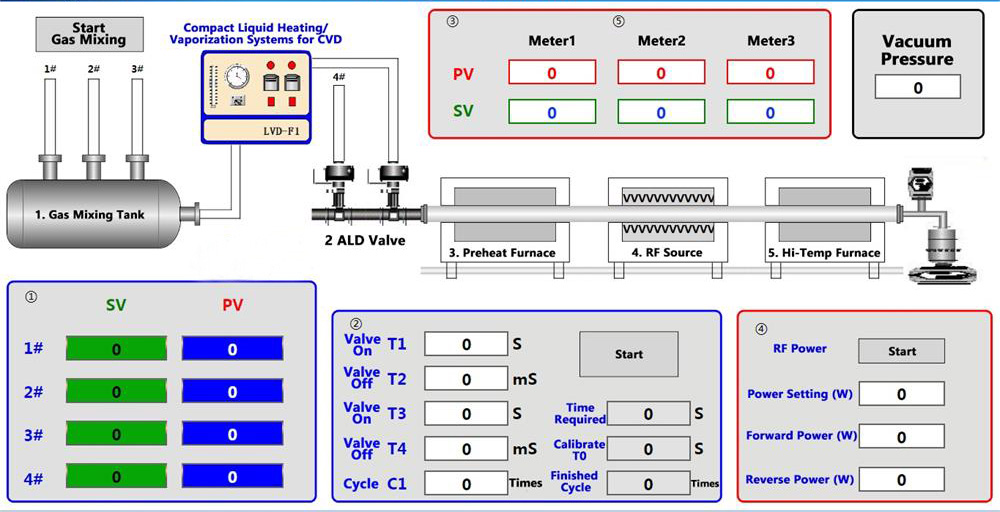

· All parameters of ALD vapor puls time , and Gas flow are controlled by PLC via a 6" touch screen panel in a mobile cart WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Control Two ALD valves with puls duation time and cycling with mico-second precisionWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Control For channels gas delivery with ±0.2%F.S via MFCWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Display vacuum pressure WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Other parameter upon request of customerWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Please click picture below to see control interfaceWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

ALD valveWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Two ALD valves with pulse controller (min 10 ms duration )WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Capable of heating with thermal actuatorsWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Liquid-Vapor GeneratorWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Automatic liquid vapor generator is included and connect to ALD valveWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Dual Zone Split Tube furnace WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Max 1100ºC for continuous heatingWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Two programmable precision digital temperature controllers with 30 segments.WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Two separate controlled Heating ZonesWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· 200mm length for each heating zoneWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· 400mm total in heating lengthWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· 250mm constant central temperature heating area if both zones were heated at the same temperatureWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· 500ºC max temperature difference between two zones with thermal blocks in betweenWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Input power: 208 – 240V AC input, single phase at max. 4KWWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Optional: ALD control system can be installed with a short tube furnace or rotation tube furnace as picture belowWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Anti-corrosive Pressure GaugeWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· 3.8x10-5 to 1125 Torr measurement rangeWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Anti-corrosive, gas-type independent WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· High accuracy and reproducibility at atmosphere for reliable atmospheric pressure detectionWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Fast atmospheric detection eliminates waiting time and shortens process cycleWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Easy to exchange plug & play sensor elementWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Click the picture to view detail spec.WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Vacuum Pump WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

( optional)WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· 10E-2 Torr vacuum can be achieved inside processing tubeWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Vacuum pump is not included , suggest you order a dry pump for CVD process by click picture belowWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

More Bubbler OptionalWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Click picture below to order bubbler or evaporator for CVD, and below right for Constant temperature control moduleWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Could add Quartz Crystal and thermocouple to monitoring thin film thickness and temperature at extra costWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Update Idea WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· You may use ALD Device to build hybrid Plasma enhanced ALD+ CVD and ALD+PVD+CVD system to grow complex materials and Powder ALD with rotation furnaceWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· ( PE-ALD+CVD) · ( PE-ALD+CVD)  ( PE-ALD+PVD +CVD)WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac ( PE-ALD+PVD +CVD)WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Warranty WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

One year limited warranty with lifetime support (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order replacements at related products below).WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

ComplianceWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Built-in Pfeiffer's pump is ELT CertificationWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· CE CertifiedWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· All electric components ( >24V) are UL / MET / CSA certifiedWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost. WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Application NotesWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Tube furnaces with quartz tubes are designed for using under vacuum and low pressure < 0.2 bars / 3 psi / 0.02 MpaWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· The flow rate for gasses should be limited to < 200 SCCM (or 200 ml/min) for reducing thermal shocks to the tubeWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°CWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

ApplicationWI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Using ALD to significant decrease the high solid–solid interfacial impedance between the garnet electrolyte and electrode materials. WI0Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|