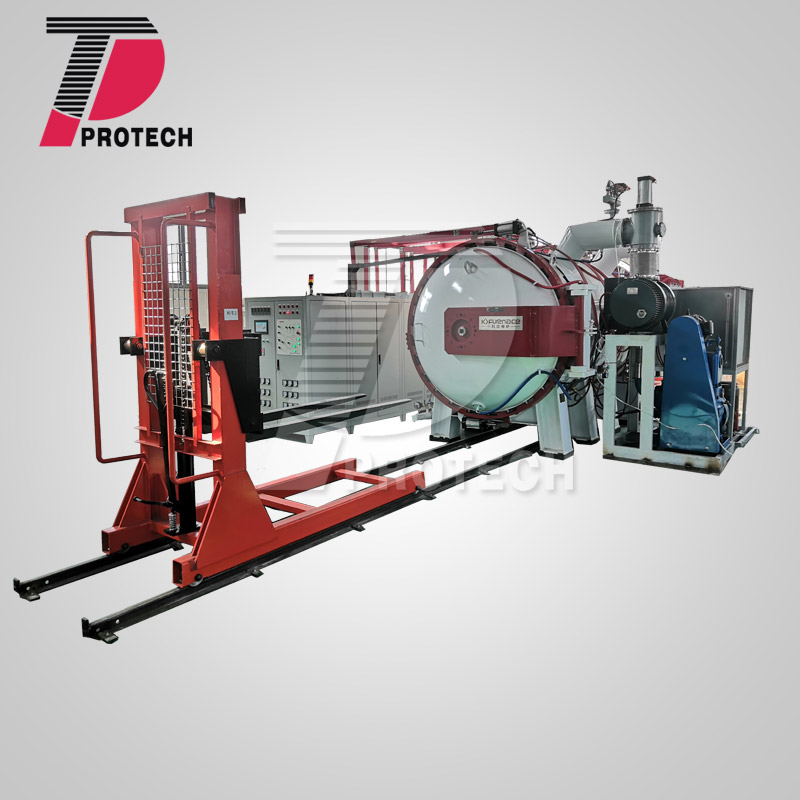

model:PT-VS1800-936CWD

High temperature graphite vacuum sintering furnace

Application: The high-temperature vacuum sintering furnace is a horizontal steel structure furnace body, and the furnace door adopts a double-door structure with two sides and side openings. It is composed of a furnace body, a vacuum system, a water cooling system.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Introduction:

The high-temperature vacuum sintering furnace is a horizontal steel structure furnace body, and the furnace door adopts a double-door structure with two sides and side openings. It is composed of a furnace body, a vacuum system, a water cooling system, an electrical part, and a feeding cart.This high-temperature vacuum sintering furnace is mainly used for heating and sintering metal refractory compound powder metallurgy materials, carbon and graphite products, ceramic materials, etc. in a vacuum state, and is widely used in metallurgy, chemical industry, petrochemical industry, high-energy physics, aerospace, electronics and other fields .

Features:

- Integrated design, compact structure, beautiful appearance.

- It adopts touch screen + PLC control mode, with high degree of automation, intuitive operation and powerful functions.

- Multiple sintering processes can be stored, and can be called directly after editing once.

- The sintering data can be recorded in real time, can be queried, and can be exported in the form of Excel.

- Multi-temperature zone temperature control, fast heating rate, good furnace temperature consistency.

- The sintering temperature is high, and the high temperature resistant and non-deformable graphite rod is used to generate heat. The long-term working temperature can reach 1800°C.

- Equipped with a vacuum unit, it can realize heat treatment of materials under high temperature and high vacuum.

Technical Parameter:

| Product name |

High temperature graphite vacuum sintering furnace |

| product display |

|

| Model |

PT-VS1800-936CWD |

| Material area size |

600×600×2600mm |

| Heating element |

graphite rod |

| Working temperature |

1800℃ |

| Number of heating zones |

Tungsten sheath thermocouple |

| ultimate vacuum |

0.5pa (empty furnace, cold state, purified) |

| Vacuum unit |

Roots pump, sliding valve pump unit (including pneumatic baffle valve, vacuum pipeline and vacuum measuring instrument, etc.) |

| voltage |

3 phase 380V |

| Total power of the whole machine |

About 480KW |

| Temperature control method |

Touch screen + PLC + transformer Multi-stage programmable temperature control |

| Furnace door locking method |

Pneumatic locking ring locking |

| inflation pressure |

0.02mpa |

| other sizes available |

| work area size(mm) |

volume (L) |

work area size(mm) |

volume (L) |

| 200*200*300 |

12 |

400*400*600 |

96 |

| 200*200*400 |

16 |

500*500*700 |

175 |

| 350*350*350 |

43 |

600*600*900 |

324 |

| More sizes can be customized |

5cMMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5cMMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5cMMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5cMMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5cMMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5cMMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac