-

-

Vacuum Furnace

-

Tube Furnace

-

Customize Furnace

Heat treatment equipment

-

-

Equipment for Ultra Hard Tools

PCD and PCBN for Ultra Hard Tools

Solution for Ultra Hard Tools

0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

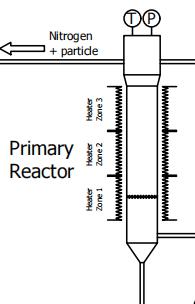

Vertical tube furnace synthesis gas pyrolysis system

| Model | PT-T1200-V3Z1 | |

| Part I Primary Reactor | ||

|

||

| Structure | Split tube furnace | |

| Tube size | OD280mm, three-heating zone 460+460+460mm | |

| Tube material | 310S | |

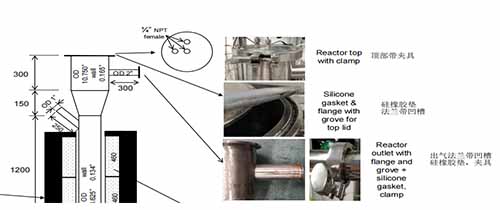

| Sealing | Reactor top with clamp; Silicone gasket&flange with grove for top lid; Reactor outlet with flange and groove+silicone gasket, clamp; |

|

| Heating element | Resistance wire with Mo | |

| Refractory material | Semi-cylinder ceramic fiber | |

| Max. working Temperature | 1000℃ | |

| Temperature sensor type | Three K type thermocouples | |

| Temperature Control | Three temperature controllers to control each zone separately 30 steps programmable PID automatic control Over-temp protection |

|

| Heating Rate | 0~20℃/min (suggestion: ≤10℃) | |

| Temperature Accuracy | +/-1℃ | |

| Working Voltage | 110-415V, 50/60Hz | |

| Max. Heating Power | 40 KW(specific according to design) | |

| Part II Particle filter | ||

|

||

| Particle filter 1 and 2 | OD100mmxH300mm, Metal mesh filter element (rated for 1 micron) |

|

| Particle filter 3 | 15L Metal mesh filter element (rated for 1 micron) |

|

| Part III Gas Buffer Tank | ||

|

||

| Volume | Stainless steel 20 L | |

| Pressure | Analog pressure gauge max. 6-10 bar Pressure sensor up to 6-10 bar |

|

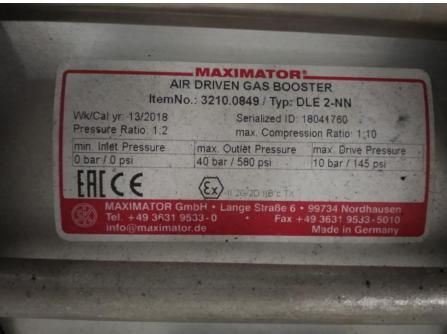

| Part IV Air driven gas booster | ||

|

||

| Max. Drive pressure | 10 Bar/145psi | |

| Max. Outlet pressure | 40 Bar/580psi | |

| Part V Float flowmeter | ||

|

||

| 4 Float flowmeters | Measuring range: 0-100L/min | |

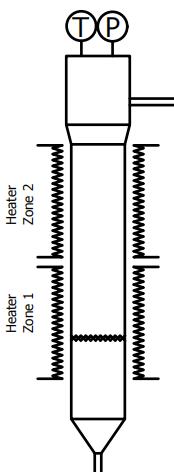

| Part VI Secondary Reactor | ||

|

||

| Structure | Split tube furnace | |

| Tube size | OD280mm, double-heating zone 690+690mm | |

| Tube material | 310S | |

| Sealing | Reactor top with clamp; Silicone gasket&flange with grove for top lid; Reactor outlet with flange and groove+silicone gasket, clamp; |

|

| Heating element | Resistance wire with Mo | |

| Refractory material | Semi-cylinder ceramic fiber | |

| Max. working Temperature | 1000℃ | |

| Temperature sensor type | Two K type thermocouples | |

| Temperature Control | Two temperature controllers to control each zone separately 30 steps programmable PID automatic control Over-temp protection |

|

| Heating Rate | 0~20℃/min (suggestion: ≤10℃) | |

| Temperature Accuracy | +/-1℃ | |

| Working Voltage | 110-415V, 50/60Hz | |

| Max. Heating Power | 40 KW(specific according to design) | |

| Part VI Afterburner | ||

| ... | ||

| Whole system with stainless steel frame | ||

Heat treatment equipment

Vacuum Furnace

Tube Furnace

Customize Furnace

Solution for Ultra Hard Tools

Equipment for Ultra Hard Tools

PCD and PCBN for Ultra Hard Tools