|

ModelSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

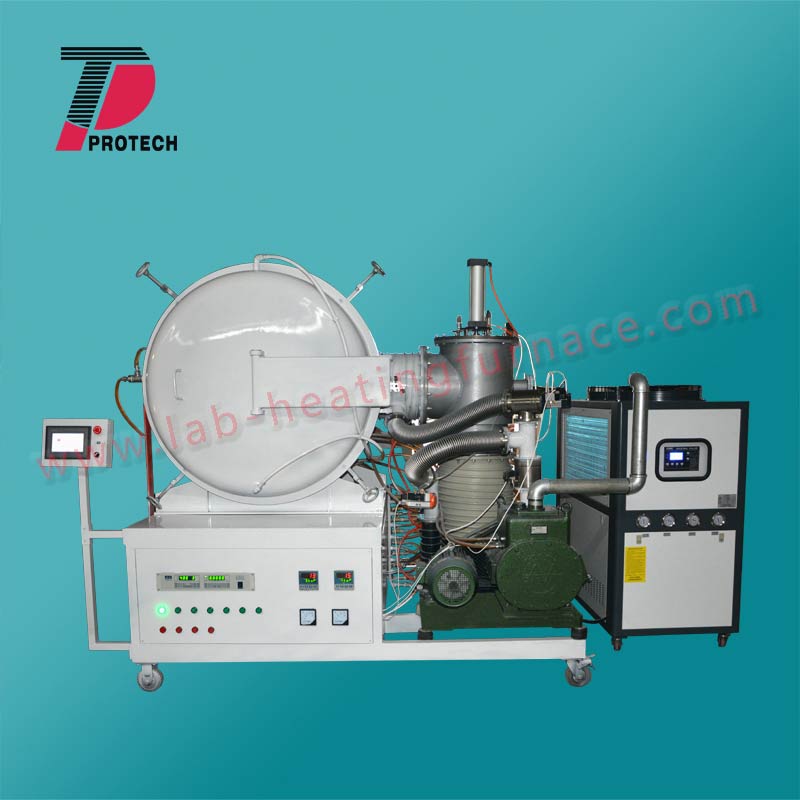

PT-V1400-64LSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Part I: Standard Parts heating SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Heating FurnaceSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Furnace FeatureSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Body structure: Double Layer steel casting support water jacket Furnace door inside is polished stainless steelSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Furnace shell: High intensity carbon steel with electrostatic spraying.SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Process using grinding mouth cavity seal sealing interface is stable and reliableSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

New type chamber lining material.Low power consumption,energy saving and pro-environment.SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

DisplaySCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

7” Touch ScreenSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Max. TemperatureSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

1400℃SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Continuous Working Temp.SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

≤1300℃SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Heating RateSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

0-10℃/minSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Heating ElementSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Molybdenum beltSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

ThermocoupleSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

S typeSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Chamber SizeSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

400*400*400mmSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Temperature ControlSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

PID automatic control via SCR power controlSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Heating curvesSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

30 segment “time - temperature” curve adjustable and PID auto controlSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Upper limited alarm and deviation alarmSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

PowerSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

380V, 50/60HZ Hz. 3 phaseSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Part 2 Vacuum pump systemSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Vacuum Pump System SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

The vacuum system is made of one set Oil diffusion pump&.One set Rotary vane mechanical pump. Max. Vacuum degree of furnace chamber is 6.67x10-3PaSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Ⅰ: Rotary Vane pumpSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Ⅱ: Dissusion pumpSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Part 3 Water chillerSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Water ChillerSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Power SupplySCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

380V 50Hz 3 phasesSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

SCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Cooling CapacitySCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

15KWSCNMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |