-

-

Vacuum Furnace

-

Tube Furnace

-

Customize Furnace

Heat treatment equipment

-

-

Equipment for Ultra Hard Tools

PCD and PCBN for Ultra Hard Tools

Solution for Ultra Hard Tools

0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

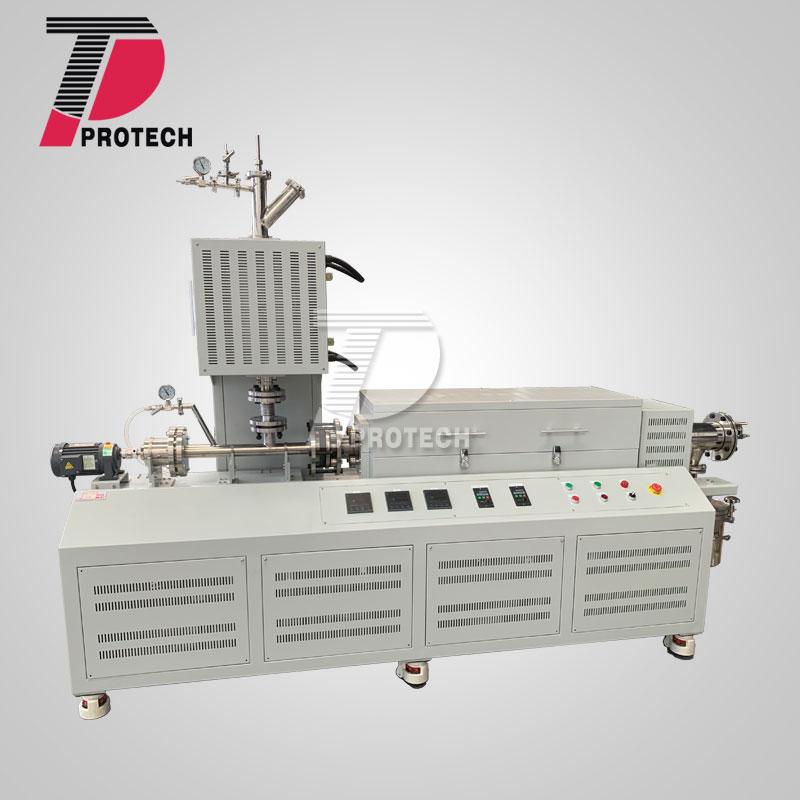

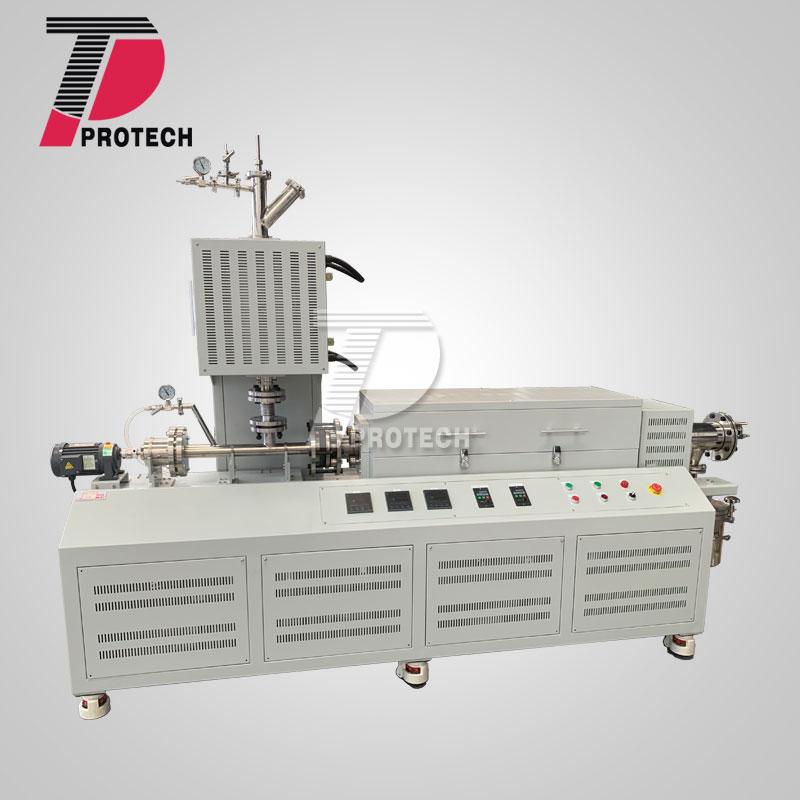

The whole system consists of one crucible furnace and a main rotary tube furnace with graphite sealing design, gas inlet and outlet with related valves are equipped, user can collect gas from the preheating furnace and main tube furnace. There are two different process technology according to client actual requirement. Click to learn more about Inclined rotary tube furnace!

Actual photo of a three temperature zone rotary tube furnace with preheating

Samples get preheated inside the crucible furnace then baffle get opened manually, sample get discharged with the screw feeder to the main rotation tube furnace and get forward continuously along with main tube rotation until to the discharged hopper, user adjust the tube rotation speed to control the resistance time. Only one 10L discharged hopper works. There are necessary thermal insulation to reduce the heat loss from the preheating furnace until to the main furnace. The main rotation tube furnace works independently, the inclination angel is adjustable from 0°to 10°, feeding hopper and discharged hopper of 10L work together.

1.The tube is rotary & multiple heating zone design for sample uniform heating, user can also set temperature gradient according to actual need.

2.Independent temperature controller. 30 steps of programmable temperature.

3.Adjustable high precision 10L screw feeder is equipped, so the main rotary tube furnace can work independently without the preheating furnace.

4.Variable frequency motor to control tube rotation speed and screw feeder.

5.Adjust tilt angle with digital angle gauge.

6. Combined aural and visual alarm for accident of over temperature & thermocouple broken, and the power supply of the heating part will cut off automatically.

7.The whole system is sealing design with inlet & outlet valves, user can collect the gas. Ferrofluid seal for the manual baffle and screw feeder, graphite dynamic seal for two ends of the main furnace.

| Product name | Main rotary tube furnace | Preheating crucible furnace |

| Model | PT-R100*900-1000 | PT-C200*300-800 |

| Display | LED | LED |

| Max Continuous Working Temp. | 1000℃ | 800℃ |

| Tube material | 310S stainless steel | 310S crucible |

| Tube Diameter | OD100mm | OD200*H300mm |

| Total tube length | 1400mm(for reference only) | |

| Hot zone length | 900mm | |

| Hot zone num. | 3 | |

| Single hot zone length | 300mm | |

| Angle of inclination | 0~10°adjustable | |

| Rotate speed | 0~10rpm adjustable | |

| Volume of hoppers | 10L | |

| Hoppers material | Stainless steel | |

| Heating Rate | 0~20℃/min | |

| Thermal Control Accuracy | +/- 1℃(for high temperature state) | |

| Heating Element | Resistance wire with Mo | |

| Thermal Couple | K type | |

| Working Voltage | 220V 50/60HZ | |

| Temperature Control | PID automatic control via SCR power control | |

| Warranty | One year warranty(not include heating element and other wear parts) | |

Actual photo of a three temperature zone rotary tube furnace with preheating

Heat treatment equipment

Vacuum Furnace

Tube Furnace

Customize Furnace

Solution for Ultra Hard Tools

Equipment for Ultra Hard Tools

PCD and PCBN for Ultra Hard Tools