0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

| Furnace Part | ||

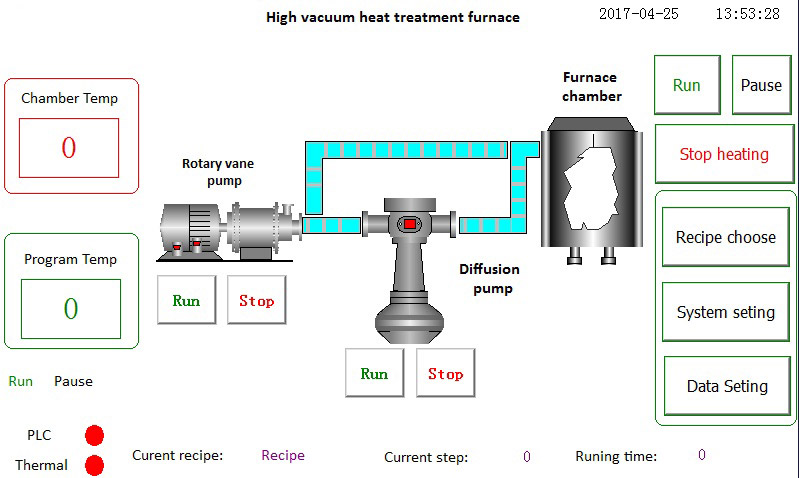

| Display | Touch Screen LCD touch screen can operate both furnace and vacuum pump systems. Over 16working programs can be set and saved Heating curves can be saved |

|

| Body structure | Double Layer carbon steel Shell with water cooling jacket. (water chiller is not included.) |

|

| Furnace shell | High intensity carbon steel with electrostatic spraying | |

| Furnace chamber | Alumina fiber insulation materials | |

| Max. Temp. | 1600℃ for short time | |

| Continuous working temp. | ≦1500℃ i | |

| Heating rate | Suggest≦ 10℃/min | |

| Heating elements | MoSi2 Heating Elements | |

| Furnace chamber size | 200*200*300mm W*H*D (can be customized according to your needs) | |

| Temperature Control | 30 segment “time - temperature” curve adjustable and PID auto control | |

| Temperature controller | Linear output current | |

| Sealing method | Vaccum tank | |

| Over-temperature alarm | Yes | |

| Over-current protection | Yes | |

| Thermocouple broken indication | Yes | |

| Temperature measuring elements | B type thermocouple | |

| Suction mouth | 1 pc | |

| Gas Outlet Port | 1 pc | |

| Gas Inlet Port | 1 pc | |

| Vacuum System Part | ||

| Max. Vacuum | 10Pa | |

| Vacuum Tank | Silicone sealing device Hand wheel locking device |

|

| Vacuum system Max. Vacuum degree of furnace chamber is 10Pa |

A vacuum pressure tan,mechanical rotary vane vacuum pump+ digital vacuum gauge  |

|

|

mechanical rotary vane vacuum pump  |

||

| After sale service | 12 month quality warranty except Consumables parts like heating elements | |