Specific Introduction:

The 1100 ℃ vacuum tube furnace is an efficient and energy-saving new type of electric furnace developed and produced independently by introducing foreign technology. It has a reasonable double-layer shell structure with a surface temperature of less than or equal to 40 ℃, and has a beautiful and elegant appearance. It is made of cold-rolled steel plates, CNC machine tools, high-precision laser cutting machines, and CNC bending machines. The surface is treated with beautiful and luxurious two-color oxidation powder for electrostatic spraying, thus achieving long-lasting, non fading, high temperature resistance, and corrosion resistance characteristics. Because the pipe diameter size is relatively large, it belongs to a type of tube furnace.VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

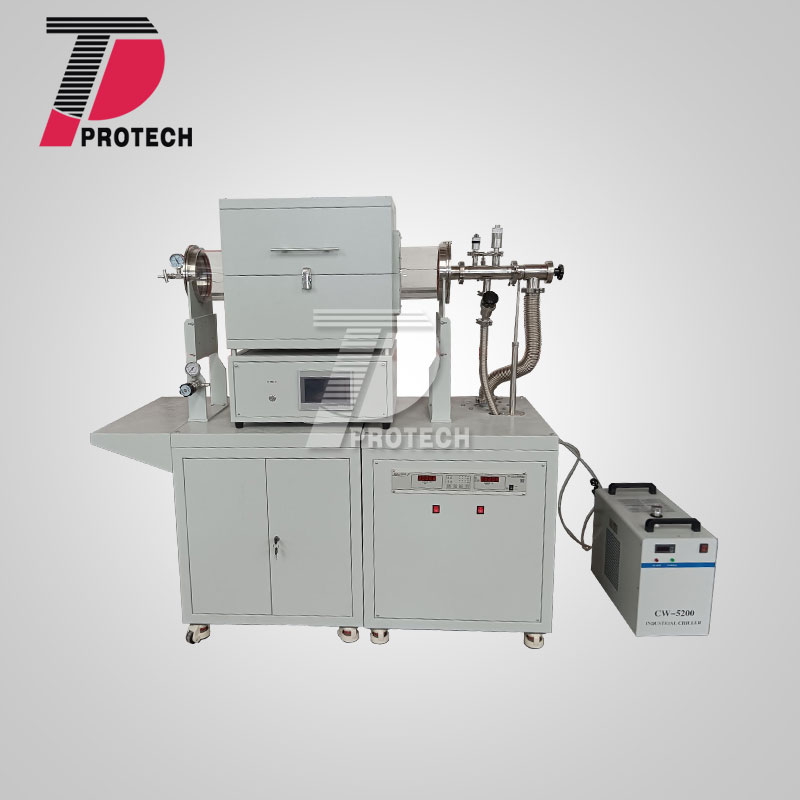

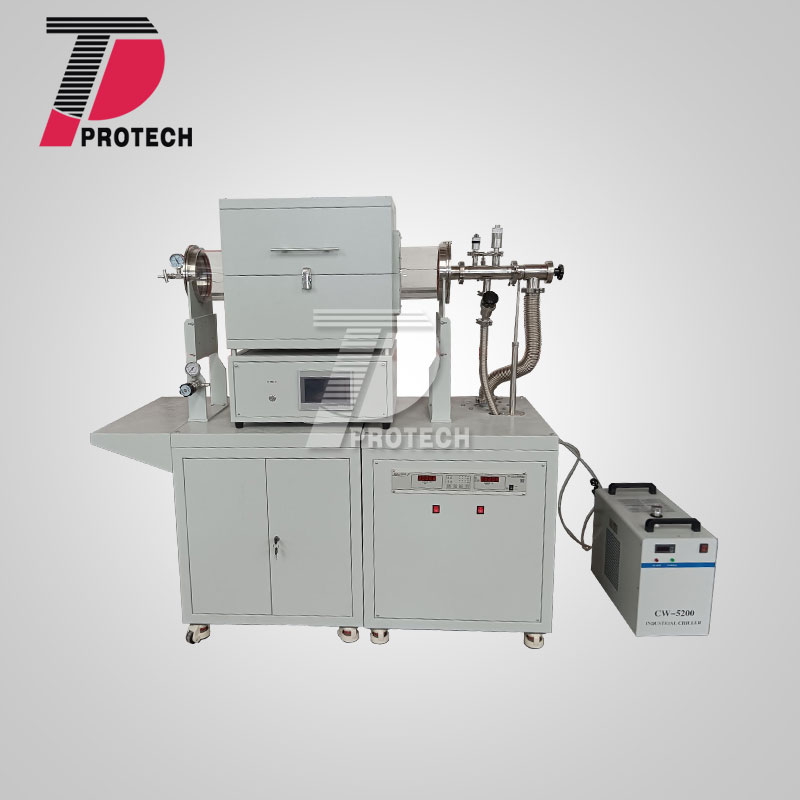

Actual photo of large caliber vacuum tube furnaceVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacApplication:VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacMainly used for the preparation of rare earth, electronic lighting, crystal annealing, bioceramics, electronic ceramics, special alloys, magnetic materials, precision casting, metal heat treatment and other industrial vacuum sintering, protective atmosphere sintering, vacuum deposition, CVD experiments, material composition determination and other occasions.VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacFeatures:VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac1. Carbon steel shell and ceramic fiber lining chamber, double layer structure, with cooling fan.VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac2. Good temperature uniformity.VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac3. Heat-resistant high-quality rubber ring sealing ensures good sealing performance.VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac4. Over temperature protection and alarm.VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac5. 30 steps programmable temperature controlled by SCR power, automatically controlled by PID.VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacTechnical parameters:

| Structure |

Carbon steel outside shellVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Two layers of Alumina fiber boardsVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1200deg.C alumina fiberVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1400deg.C alumina fiberVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Cooling fans |

| Tube |

Quartz tube OD.200mm×Len.800mm VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Sealed with flanges and rubber rings (Can be customized according to customer needs) |

| Heating zone length |

440mm(Single zone) (Can be customized according to customer needs) |

| Maximum Temperature |

1200℃VcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

(Suggestion: Lower than 1100 deg.C) |

| Temperature sensor |

N-type Thermocouple |

| Temperature Control |

30 steps programmableVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

PID automatic controlVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Over-heated protection |

| Heating Rate |

0~15℃/min (suggestion: ≤10℃) |

| Temperature Accuracy |

+/-1℃ |

| Heating Element |

Resistance wire |

| Vacuum system |

Mechanical vacuum pumpVcoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Diffusion vacuum pump |

| Warranty Period |

1 year (Lifetime support) |