0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

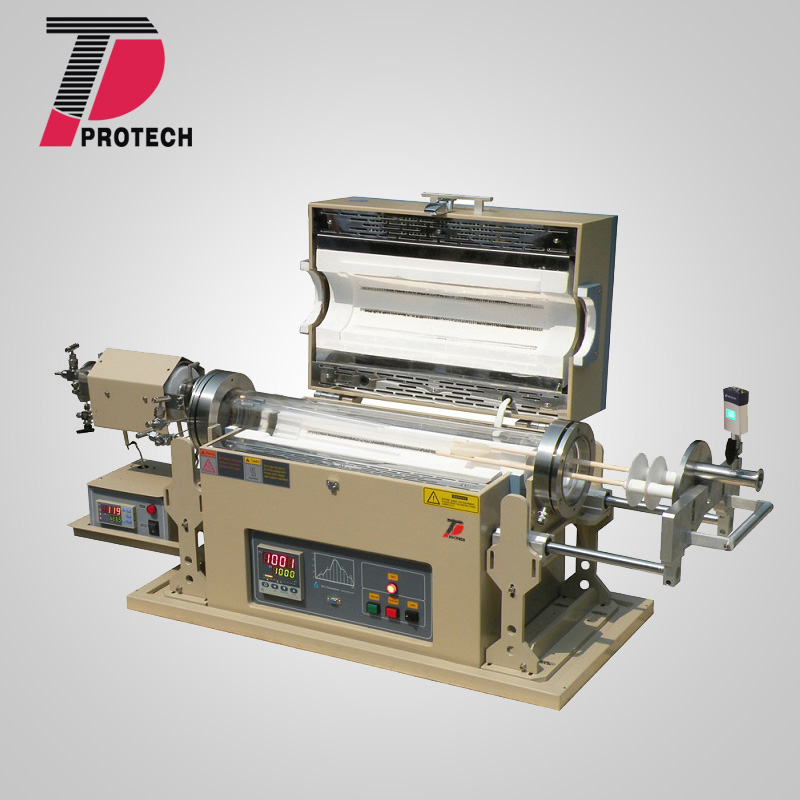

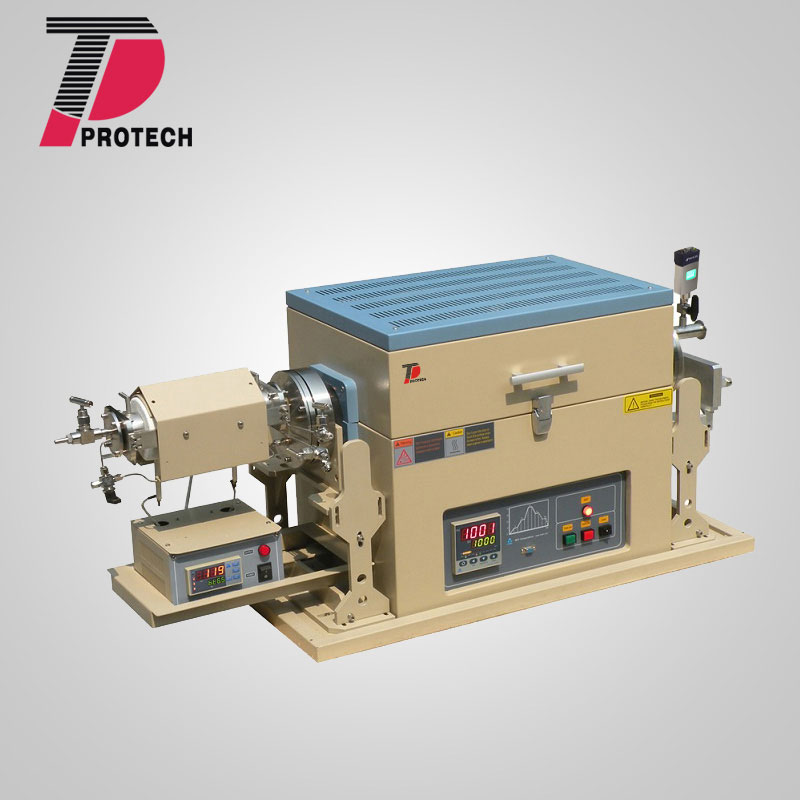

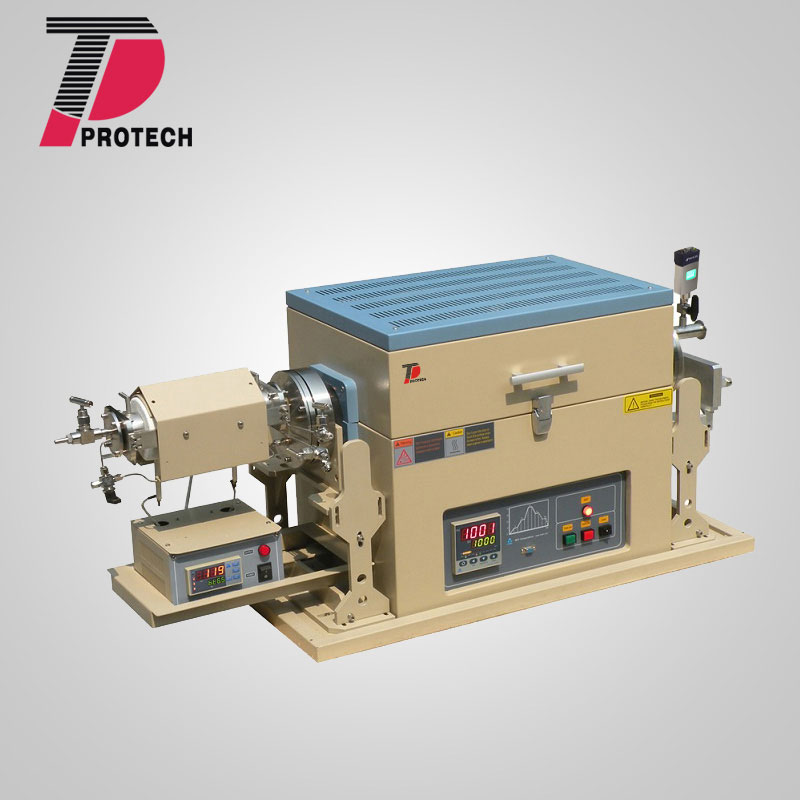

PT-1200X is a compact 1100°C CVD tube furnace with precursor sublimating attachment. Totally four-channel gas inlets are built on the sublimation which allows feedings of various gases to carry the source vapor into the main heater for further decomposition and deposition. The sample holder fixture mounted on the right flange is slidable for easy sample loading/unloading. Such a system configuration is suitable for growing a wide range of transitional metal dichalcogenides (such as MoSe2, MoS2...) and wide bandgap semiconductors (such as h-BN) layers on substrate up to 3" diameter.

Technical Parameter:

|

Furnace and Preheater |

Compact CVD furnace system is modified from PT-1200X-100 single zone tube furnace: · 4.33" O.D x 4.05" I.D x 29.13" Length quartz tube · 1100ºC Max. working temperature · Water cooling flange on right-side is slidable for easy sample loading · Water cooling flange on left-side between the heater and furnace is used for pre-heated gas input and sealing Four-channel gas inlet ( 1/8" Dia tube and tube fitting) are built-in on the left side flange One small heater is attached to the left side flange of the furnace to preheat input gas, liquid, or evaporate solid chemical, which will be then delivered to CVD furnace: · Please click picture left for more details: · Flange on the left side is for gas sealing and input |

|

|

· CVD Furnace: 440 mm · Constant temperature zone: 100 mm · Gas Heater: 150mm |

|

|

· CVD Furnace: Max heating temperature: 1100°C ( < 2 hour ) Continuous working temperature: 200~1000°C Max heating & cooling rate: 20°C/min · Heater: Continuous working temperature: RT~600°C Max heating & cooling rate: 20°C/min |

|

Temperature Control |

· CVD Furnace and Heater (separate temp control): Digital controllers with PID/self-tuning functions and 30 segments programmable Thermocouple: K type thermocouples, which feed through the right side flange and control furnace temperature. Control accuracy: +/- 1°C RS485 Communications Port |

|

|

The right flange of CVD furnace · Water cooling to prevent sealing o-ring from melting (water cooler is not included, please click water chiller to order) · KF25 vacuum fitting (to a vacuum pump, please click to order a pump, vacuum hose, valve and sealing gasket) · Slidable for the customer to easily and fast push/pull in/out sample · One quartz wafer holder ( 3" Dia. ) is included and the flange with heating radiation block · An anti-corrosive capacitance diaphragm gauge is included Left flange (between CVD Furnace and Heater) with four 1/8'' fittings for 1/8'' tube: · Two 1/8'' fitting on the flange for independently and directly delivering any gas into the CVD furnace · One 1/8'' fitting for delivering heated gas from heater to CVD furnace · One 1/4'' fitting for bypassing the gas (without heating) to the CVD furnace (inside the CVD furnace, the gas tube is merged with the heated gas pipe by a T fitting) Note: How gas pipe assembled in the CVD furnace through above 1/8'' fitting: · One 1/4'' quartz tube delivers the vapor gas from heater(also the bypass gas by a T fitting) · Two 1/4'' quartz tube delivery extra gas via the two separate 1/8'' fitting on the big furnace left the flange · These three 1/4'' quartz tubes inside CVD furnace is in parallel and vertically 1'' higher than sample holder · These three 1/4'' quartz tubes can be easily removed to clean or replaced once get stuck or corroded Heater: · Left flange: one 1/8'' gas fitting to deliver gas to the heater for pre-heating and then to CVD furnace · On the right side to CVD furnace with necessary thermal block material to minimize the temperature gradient at the interface between the heater and CVD furnace · Furnace Chamber Installation · 2- 1/4" pipe adapter is installed on each flange |

|

|

For direct liquid CVD ( DLCVD), you may consider below devices for liquid injection: |

|

|

· One year limited warranty for electrical parts. ( Consumable parts such as processing tubes, o-rings and etc are not covered by the warranty) · You may order replacement quartz tube here. |

|

Laptop, software & WiFi Control (Optional)f |

· Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for immediate use. · Temperature Control System enables the user to edit temperature profile, manage heat-treatment recipe, record and plot data for PT furnaces. · A wireless remote control provides up to 300 meters operating range. · Above features are available upon request at an extra cost. Please contact us for more information. |

|

|

· The tube furnaces with quartz tube are designed for use under vacuum and low pressure <0.2 bars · Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. · Vacuum pressures may only be safely used up to 1000°C · The flow rate for gasses should be limited to< 200ml/min) for reducing thermal shocks to the tube |

|

|

|