Function Feature1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1. This organic small molecule purification equipment's (apophorometer)main usage is sublimate organic mixed material to purify(recrystal after evaporation).The main object is organic material with sublimation feature mixed material with low characteristic(such as organic acousto-opticproduct)or nanometer material.1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. Our company can manufacture various specifications apophorometer(small molecule purification)equipment like research&equipment,pilot and industralization1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

subliamtion process1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Separation of the mixture;1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Evaporation of each component-control the heating temperature to be lower than the vaporization temperature of the material;1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Recrystallization——deposition recrystallization along the temperature gradient1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Technical Parameter1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1、heating element:KTL resistance wire1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2、heating zones:3zones,3 points temp. control independantly1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3、heating zone length:200mm+300mm+200mm (customizable)1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac 4、temp. range:RT-800℃,Continuously adjustable1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5、Temp.controll:Adopted PID automatic and double control by digital industrial instrument and PLC1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

6、Paperless record: built-in storage and record of running process data, external USB interface, you can connect a computer to copy data with one click.1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

7、Structure description: ① The equipment is opened in half. ② Equipped with a high-precision mass flow meter at the feed end to accurately control the gas flow, which can realize the expansion and adjustment of the production process. ③The system adopts automatic technological process and sets the process with one-key operation. Reducing human factors, process reliability can reach 99.9%.1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

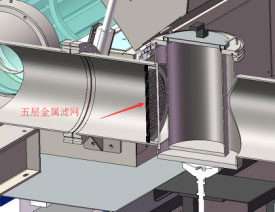

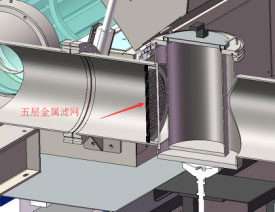

8、Filter way:Multi-level filter protection device are various lever microporous metal mesh ,nitrogen condensation embedded 1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

9、The cavity adopts internal and external quartz tube devices, the structure can ensure that the vacuum chamber tube is not contaminated, and maintain a high vacuum degree. It is easy to clean, and each section of the inner material tube is easily distinguished after sublimation, which can ensure the certified product and purity and yield (maximum sublimation rate is 97%, related to materials and configuration). The tube is big at one end and small at the other end, but can be connected between two pairs. The length of each section matches the temperature zone of the heating furnace.1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

10、The vacuum end uses a direct connection between the main pipe and the molecular pump to ensure the high vacuum requirements in the experiment. Working vacuum: the temperature in the sublimation zone and the insulation zone is about 300 ℃ ± 10 ℃, without loading any sample, the vacuum degree within half an hour 10-4Pa.1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

11、There is a cold trap absorber between the turbo molecular pump and the main heating quartz tube. The front end of the oil pump is equipped with a dust filter, the oil pump outlet is equipped with an oil mist filter, and it is used with a cooling circulation pump. Its output temperature is ≤-30 ℃.

Details1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1、Observation windows at both ends of the furnace tube1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2、Filter protection device1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3、Molecular pump set1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4、Full range gauge1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1P6Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac