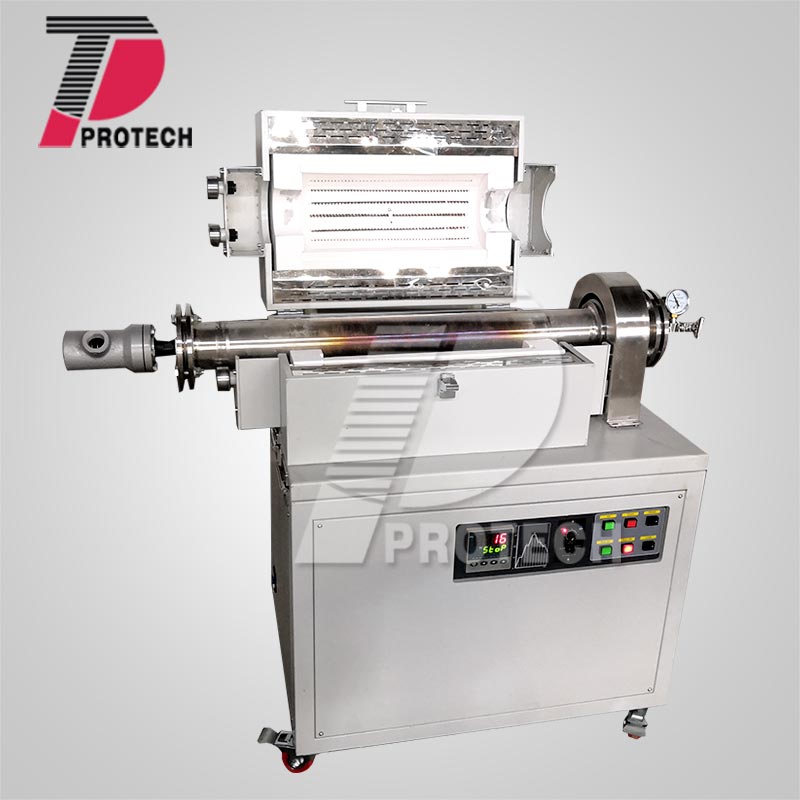

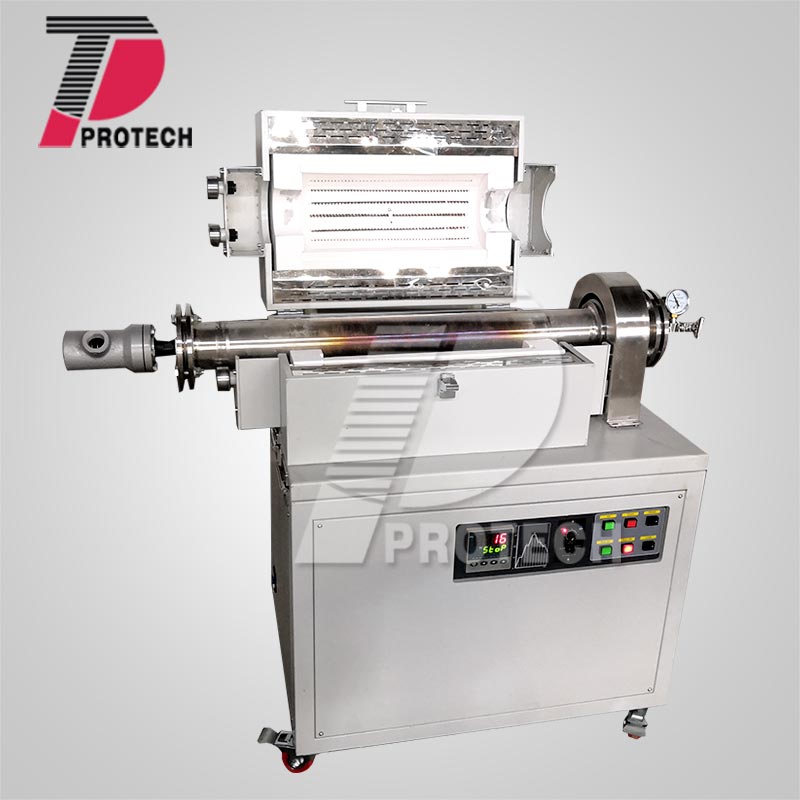

model:PT-T1000-H100-X

1000℃ Rotary Tube Furnace

Application: It is mainly used for high-temperature material synthesis and processing, such as nanomaterial preparation, ceramic sintering, catalyst activation and metal heat treatment. It is widely used in new energy, chemical industry, metallurgy and scientific research fields to support continuous production and precise temperature control needs.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Main technical parameters of the equipment:3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Product Name: 1000℃ Rotary Tube Furnace3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Product Model: PT-T1000-H100-X3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Furnace material: Furnace using alumina polycrystalline fiber3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Furnace tube size: Φ100×440mm (Can be customized according to customer needs)3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Heating zone: 440mm (Can be customized according to customer needs)3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Furnace tube material: 310S stainless steel tube3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Working temperature: ≤650℃3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Maximum temperature: 1000℃3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Heating element: Molybdenum resistance wire3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Temperature control accuracy: ±1℃3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Temperature control method: intelligent 30-segment PID programmable control3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Temperature control protection with over temperature protection function3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Flange joint Equipped with two stainless steel vacuum flanges, a mechanical pressure gauge has been installed, and both ends of the furnace tube are insulated with high-temperature cotton3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Sealing system The furnace tube and flange are extruded and sealed by silicone O-ring, which is easy to remove, can be removed repeatedly, has good air tightness, and can be vented with argon, nitrogen and other gases3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Heating rate: 0-20℃/min, 10℃/min recommended3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Tilt angle: 0-15 degrees (adjustable)3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Rotation structure: Adopt industrial rotation method, the furnace tube can rotate at 360°3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Temperature Test Element: N Type Thermocouple3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Provide related accessories Crucible hook, high temperature gloves, thermocouple, furnace plug, instruction manual, warranty card, etc.3XWMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

After-sales service 12-month warranty, lifetime warranty (except wearing parts)