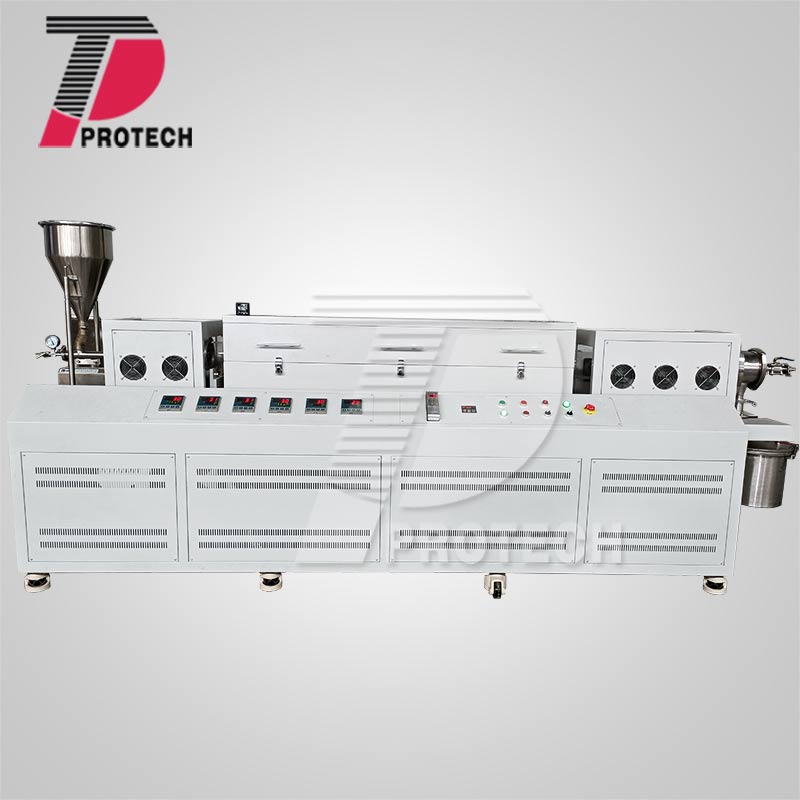

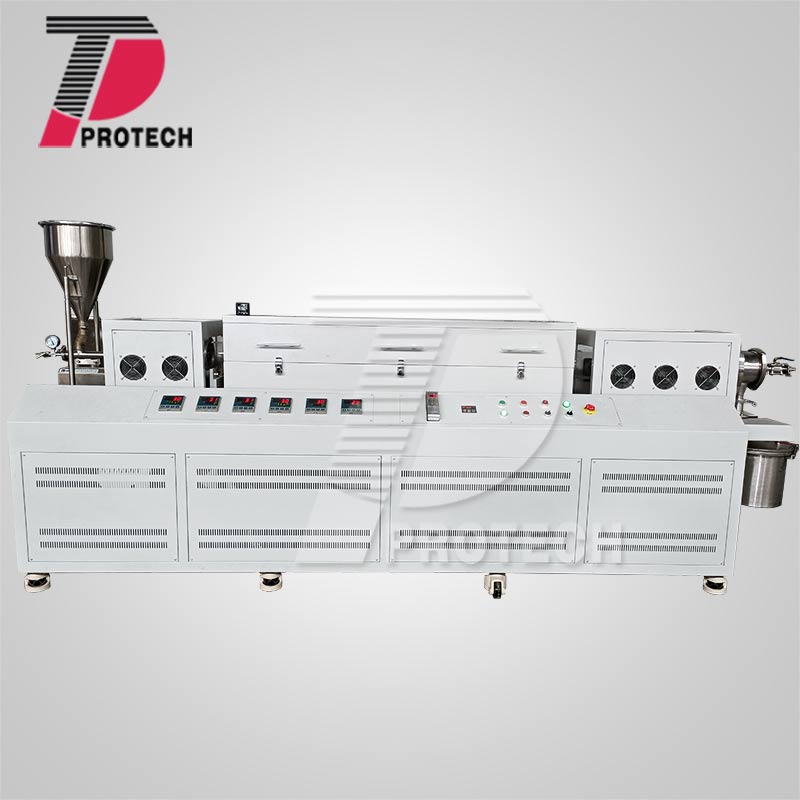

model:PT-R150*1800-1000

High Precision Control Vibration Feeding Rotary Inclined Tube Furnace

Application: High precision control vibrating feed rotary inclined tube furnace is mainly used for powder or small blocks calcination under atmosphere, vacuum or sealing environment. Adopt continuous feeding and discharging method. The tube is a rotary multi-heating zone design, the sample is heated evenly, and the user can also set a temperature gradient.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Design FeaturesdygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1. The tube is a rotary multi-heating zone design, the sample is heated evenly, and the user can also set the temperature gradient.dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. Independent temperature controller. 30-level programmable temperature.dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. Continuous feeding and discharging method.dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4. Microprocessor controlled stainless steel vibrating feeder and hopper.dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5. Rotary mechanism with corrosion-resistant design.dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

6. Adjustable speed and tilt angle.dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

7. Sound and light combined alarms such as over temperature and thermocouple disconnection will automatically cut off the power supply of the heating part.dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

dygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Specification

| Model |

PT-R150*1800-1000 |

| Display |

LED (LCD Can be customized according to customer needs) |

| Working Temperature |

≤1000℃ |

| Heating Rate |

0~20℃/min |

| Thermal Control Accuracy |

+/- 1℃ |

| Tube material |

Quartz |

| Tube Diameter |

OD150mmdygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

(Can be customized according to customer needs) |

| Total tube length |

2400mmdygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

(Can be customized according to customer needs) |

| Hot zone length |

1800mmdygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

(Can be customized according to customer needs) |

| Hot zone num. |

5 |

| Single hot zone length |

360mmdygMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

(Can be customized according to customer needs) |

| Heating Element |

Resistance wire with Mo |

| Thermal Couple |

N type |

| Angle of inclinationAngle of inclination |

0~10° |

| Rotate speed |

0~10rpm |

| Volume of hoppers |

20L |

| Working Voltage |

As required |

| Temperature Control |

PID automatic control via SCR power control |

| Warranty |

One year warranty(not include heating element and other wear parts) |