0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

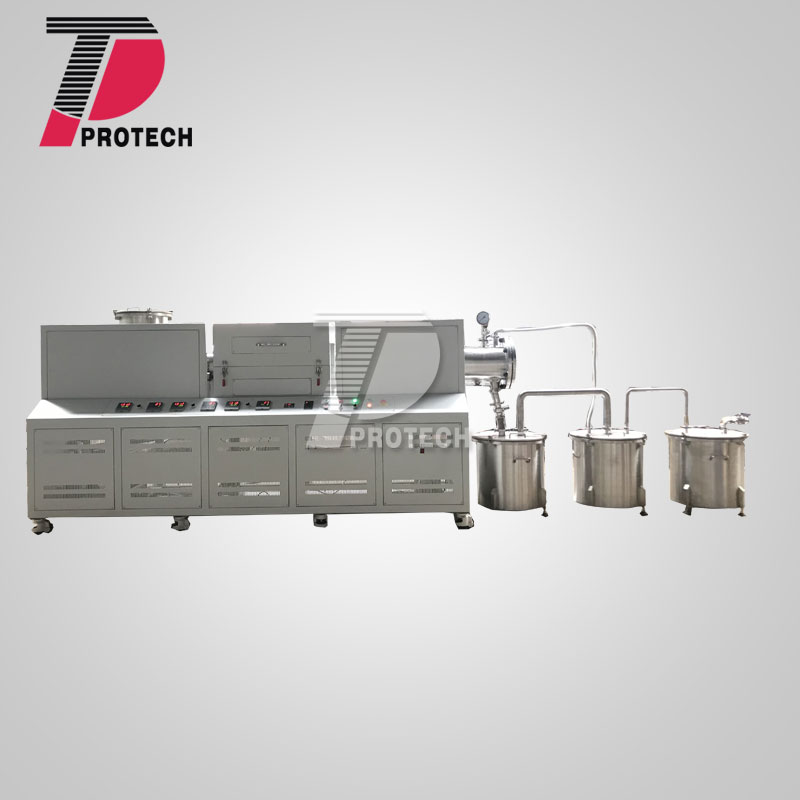

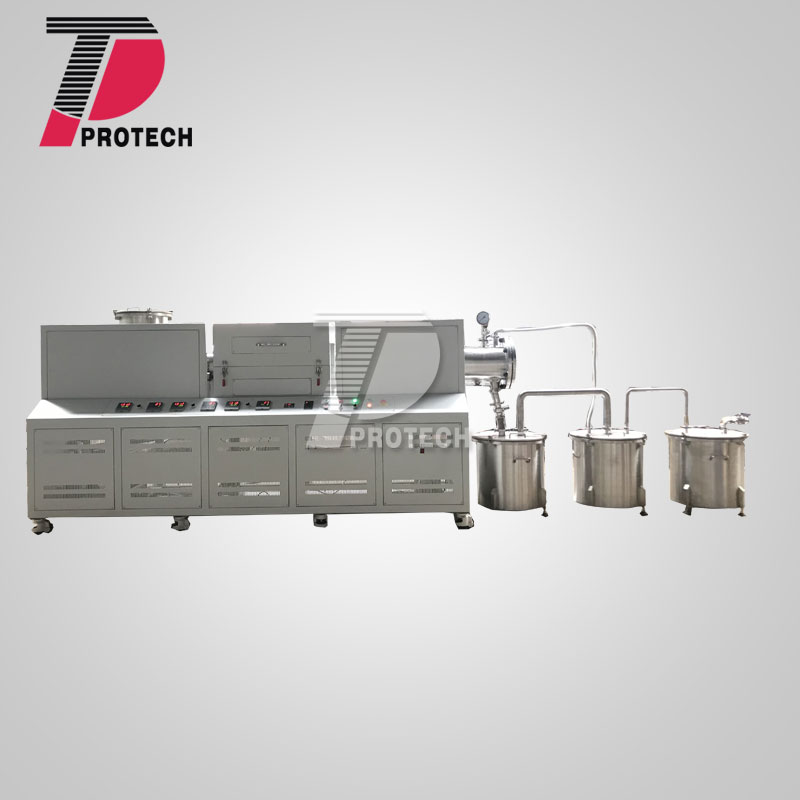

| Model | PT-RT1000-3Z |

| Structure |

Carbon steel outside shell Alumina fiber lining Double-layer structure with cooling fan Split type |

| Tube Material | Hot zone Hastelloy Two side Stainless steel tube 200mm inner diameter |

| Sealing | The left flange: Feeding system(Screw feeder) with stainless steel hopper 30L and gas-in port. The right flange: Stainless steel collection bottles, rotatory joint, vacuum pump connection port. |

| Vacuum pump | VRD-24 Rotary vane pump |

| Heating zone length | 500mm-600mm (3 hot zone) |

| Working Temperature | 1000℃ (continuous) |

| Temperature sensor type |

Total number for thermocouple is 6. 3 K-type thermocouple for 3 heating zone( heating ) 3 K-type thermocouple in the tube ( monitoring)(when the temperature in the tube below than 1000C, the furnace will heat up ) |

| Heating method | Preheating the furnace to 1000 degree, then feed the material to the hot zone) |

| Tube function | Rotating and tilt function(Tilt angle is 10°) |

| Temperature Control | 30 steps programmable PID automatic control Over-temp protection |

| Heating Rate | 0~15℃/min (suggestion: ≤10℃) |

| Temperature Accuracy | ±1℃ |

| Heating Element | SiC heating element |

| Tube Rotating speed | 0-20r/m (Clockwise and anticlockwise) |

| Tube Tilting angle | 10°. |

| Warranty Period | 1 year (the consumable parts such as tube is not included) |