|

product nameKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

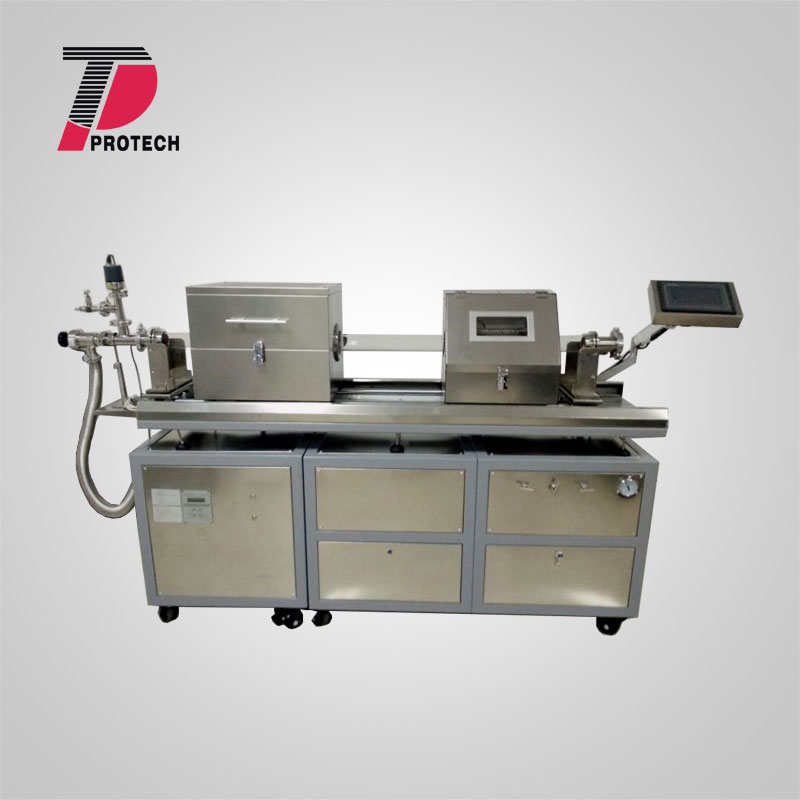

High vacuum PECVD systemKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Slide rail tube furnace partKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Product numberKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

PT-T1200KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Furnace tube sizeKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Φ50mmX1600mmKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Furnace tube materialKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Quartz tubeKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Heating zoneKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

300mmKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Operating temperatureKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

1100°CKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Maximum temperatureKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

1200°CKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Temperature control methodKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

K-type thermocoupleKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

way to controlKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Touch screen control, with independent rocker arm, you can adjust the angle of the temperature control screen according to actual needs, making it more convenient to useKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Temperature control accuracyKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

±1℃KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Temperature control protectionKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

With over-temperature and burnout protection functionKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Heating rateKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

0-20ºC/min, recommended 10ºC/minKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Heating elementKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Molybdenum resistance wireKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Operating VoltageKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

AC 220V single-phase 50HZ (circuit voltage users can choose to customize)KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

heating powerKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

3KWKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Furnace materialKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Alumina polycrystalline fiberKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Furnace structureKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

The furnace body has a slide rail, which can realize rapid heating and coolingKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Flange jointKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Standard configuration is equipped with two stainless steel vacuum flanges, mechanical pressure gauge and stainless steel globe valve have been installedKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Sealing systemKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

The furnace tube and flange are extruded and sealed with a silica gel O-ring, which is convenient to remove and can be removed repeatedly, and has good air tightness.KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

caseKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Stainless steel housingKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

OptionalKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Auxiliary cooling fanKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Vacuum system partKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

nameKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Vacuum systemKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

The main parametersKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

1. Using imported Agilent high vacuum molecular pump set, the ultimate vacuum degree can reach 10-3paKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. KF25 quick connection, stainless steel bellows, manual flapper valve and flange, vacuum pump connection;KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. Digital vacuum display, its measuring range is 5×10-5-1500mbar, with high measuring accuracyKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Pneumatic system partKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

nameKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Four-way mass flow meterKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

The main parametersKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Four-channel precision mass flow meter: touch screen control, digital display, automatic control. Flow range Flow range:KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1. MFC 1-MFC4: 0-1000sccm adjustableKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. A mixing tankKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.4 stainless steel needle valves are installed on the left side of the gas supply system, which can manually control 4 kinds of gases;KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4. Air inlet and outlet: 3 in and 1 outKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Flow control: manual rotary adjustmentKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Connection mode: double card sleeve connectionKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Plasma power supply partKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

nameKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

500W plasma power supplyKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Power rangeKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

0-500W (continuously adjustable)KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

working frequencyKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

13.56MHZ+0.005%KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Operating modeKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Continuous outputKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

RF output impedance interfaceKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

N-type, female (50Ω)KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Power stabilityKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

≤2WKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Maximum reflected powerKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

70WKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Power protection settingsKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

DC over current protection, power amplifier over temperature protection, reflected power protectionKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Supply voltage/frequencyKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Single-phase AC (187V-253V) 50-60HZKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

cooling methodKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Wind coolingKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Overall sizeKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

88X483X550 MMKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

Total WeightKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

13.5KGKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

CertificationKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

ISO certification, CE certificationKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

|

After-sales serviceKYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

One year warranty and lifetime warranty (consumables: high temperature sealing ring, furnace tube, heating element, etc. are not covered by the warranty)KYoMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|