EXPLORE THE NEW TRENDS AND ADVANCED TECHNOLOGIES IN THE HEAT TREATMENT EQUIPMENT INDUSTRY

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

When choosing a continuous feeding and discharging rotary tube furnace, the following key factors need to be considered to ensure the selection of equipment suitable for your needs. We need to consider the following aspects.

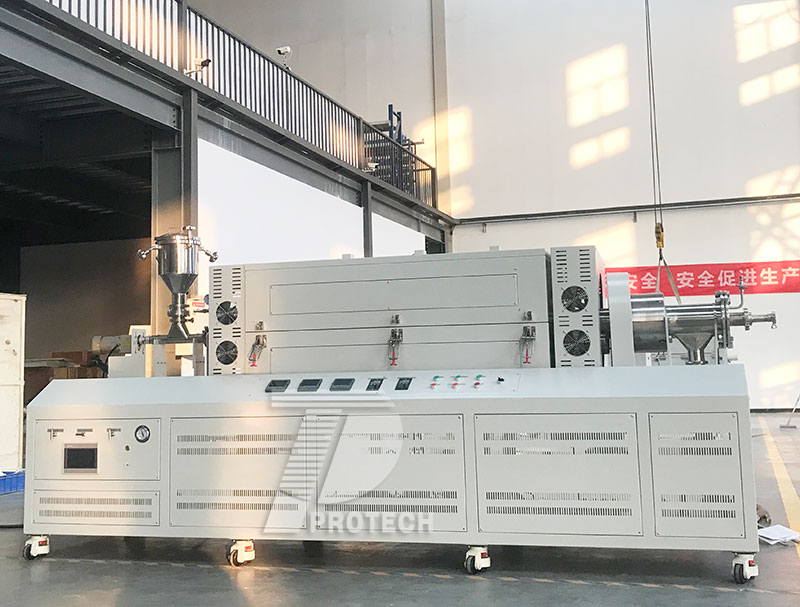

Continuous production of rotary tube furnace (click on image to view product details)

Heating method: Determine the heating method you need, commonly including resistance heating, induction heating, etc. Choose the appropriate heating method based on the characteristics of the material and process requirements.

Heating temperature range: Determine the maximum and minimum heating temperature range you need, and choose a continuous inlet and outlet rotary tube furnace that can cover the required temperature range.

Heating zone length: The length of the heating zone is determined based on the processing time and heating requirements of the material. A longer heating zone can provide longer processing time, helping to ensure sufficient heating of the material.

Material and Pipeline Design: Ensure that the furnace tube material and design of the selected equipment can meet the characteristics and process requirements of the materials you handle. For example, selecting furnace tube materials that are resistant to high temperature and corrosion, and ensuring that the pipeline design can achieve uniform heating and cooling. The commonly used furnace tube materials are quartz tube, aluminum oxide tube, stainless steel tube, mullite tube, and silicon carbide tube. Different furnace tubes have different heating temperatures, which need to be selected according to the needs.

Temperature control: Select a rotary tube furnace with high-precision temperature control to ensure that the temperature inside the furnace remains constant or changes according to the set program. This usually involves thermocouples or other temperature measuring components, as well as intelligent temperature control systems.

Rotating function: One of the key features of a rotary tube furnace is the rotating function of the furnace. Therefore, a furnace with stable rotational performance should be selected to ensure that the materials are uniformly heated in the furnace and improve the heat treatment effect.

Material handling: Consider the material handling capacity of the furnace, including the design of continuous feeding and discharging. Ensure that the furnace can effectively handle the required materials and that the feeding and discharging process does not have adverse effects on the temperature control or rotation function of the furnace.

Heating control system: Select equipment with a good heating control system that can reasonably control the heating temperature and heating rate to ensure stable processing effect and product quality.

Production capacity and output: Determine the production capacity and output of the continuous feeding and discharging rotary tube furnace based on your production needs. Choose equipment that can meet your expected output and ensure its stability and reliability.

Safety and Maintenance: Choose equipment with good safety and easy maintenance, including safety protection devices, easy to clean designs, etc.

Budget considerations: Choose the appropriate equipment based on your budget situation. Consider factors such as equipment price, operating costs, and maintenance costs, and choose products with high cost-effectiveness.

So, when choosing a continuous feeding and discharging rotary tube furnace, it is necessary to comprehensively consider factors such as heating method, heating temperature range, heating zone length, material and pipeline design, heating control system, production capacity and output, safety and maintenance, budget considerations, etc., and make a reasonable selection based on actual needs to ensure that the selected furnace can meet actual needs and expected effects. It is recommended to have detailed communication with the manufacturer before purchasing to obtain more information about the performance, use, and maintenance of the furnace.Click to learn more Inclined rotary tube furnace! Or click on online customer service to learn more about product information!