|

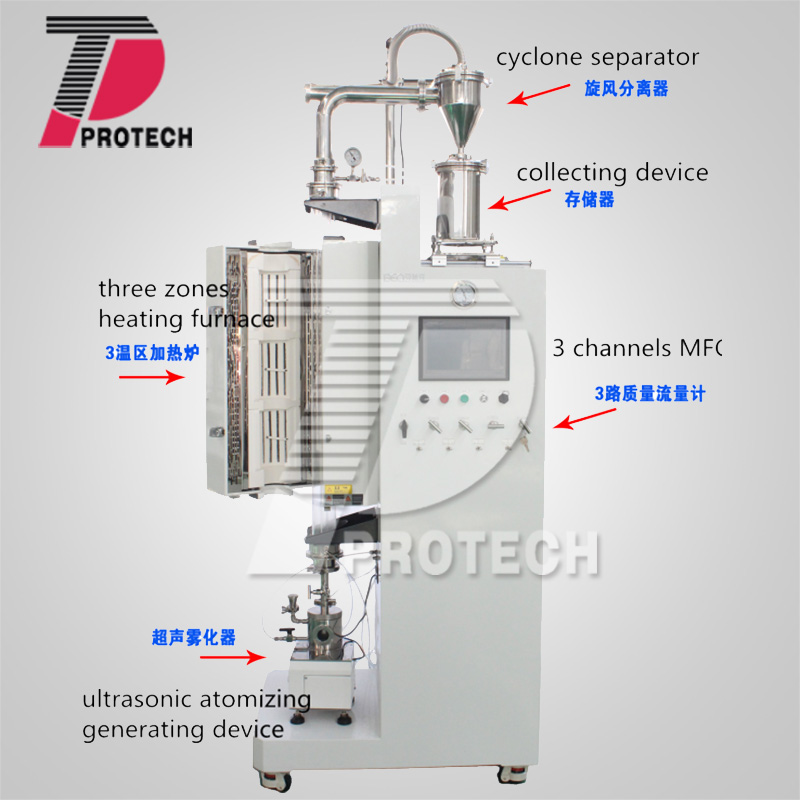

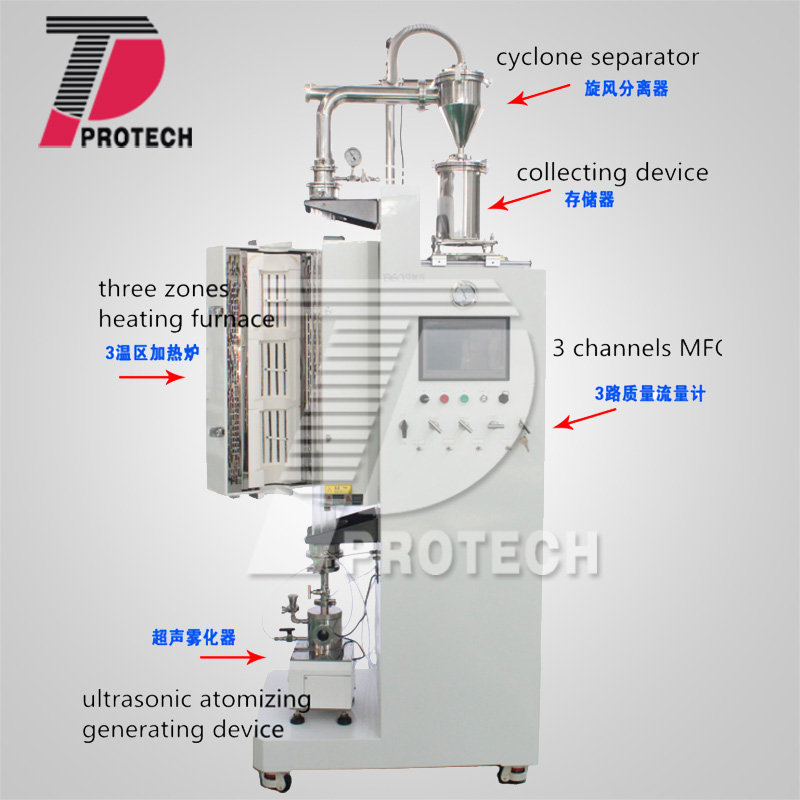

Furnace |

|

Max. Temp |

1200°C |

|

zone length |

Heating:200+200+200mm2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Constant:400mm |

2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Temperature Controller2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

l PID automatic control and auto-tune function.2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

l 30 programmable segments for precise thermal processing.2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

l Built-in protection for the over-heated and broken thermocouple. 2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

l Operation interface is 10 “ touch screen2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Heating Elements2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

· Resistance wire, Fe-Cr-Al Alloy doped by Mo2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Temperature Accuracy2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

+/- 1 °C |

Processing tube2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Material:high purity quartz2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Size:outer 80mm, inner 50mm |

|

Gas supply system |

|

Connector style |

Double cutting ferrule stainless steel connector |

|

Standard range(N2) |

50sccm、100sccm、200sccm、500sccm; optional |

|

Accuracy |

±1.5%FS |

|

Response time |

Gas characteristics:1~4sec2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Electrical characteristics:10sec |

|

Linearity |

±0.5~1.5% |

Working pressure difference range2BsMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

0.1~0.5MPa |

|

Max. pressure |

3MPa |

|

Pressure vacuum gauge |

-0.1~0.15 MPa, 0.01 MPa/grid |

|

Vacuum unit |

|

pumping |

63m³/h |

|

Oil capacity |

2L |

|

Rotation rate |

1440rpm |