|

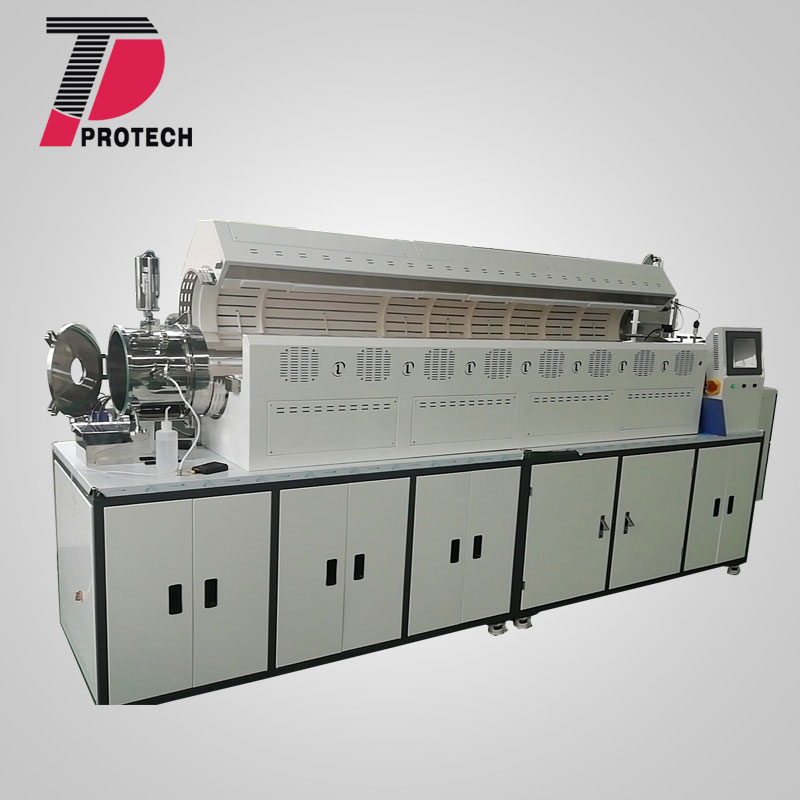

Equipment size8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Φ300*2800mm8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Tube size8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Φ300*3000mm8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Max loading8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

20Kg8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Heating element8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

KTL resistance wire8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Hot zone8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

3-8 zones optional8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Max temperature8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Room temperature-1200C continuous adjustable 8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Temperature control8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

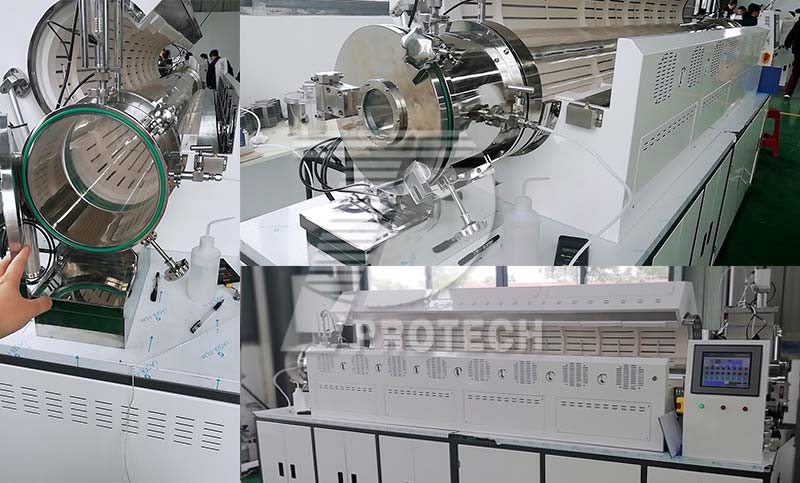

Man-machine interface plus PLC control, 10-inch LCD screen control, digital industrial control instrument dual control, industrial intelligent temperature control instrument and software to achieve dual control, PID control8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Paperless record8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Built-in storage and recording process data, external USB interface, you can connect the computer to copy data with one click8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Structure description8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

① The equipment can be opened by electric, and cooling system can be automatically controlled. A controlled cooling rate can be achieved.8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

② Equipped with a 2-way high-precision mass flow meter system at the feed end to accurately control the gas flow, which can realize the expansion and adjustment of the production process.8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

③The system adopts automatic technological process and sets the process with one-key operation. Reduce human factors, process reliability can reach 99.9%;8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

④Mechanical pump system: 1pa, additionally equipped with a fine-tuning system to ensure that graphene can be grown under stable negative pressure; a graphene film with a daily output of 200,000 square centimeters can be realized8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Chamber8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

Using internal temperature control and external temperature control to switch between each other to prevent the uneven temperature field caused by quartz refraction and scattering8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

|

Gas system8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |

3-ways mass flow meter8rzMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac |