0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

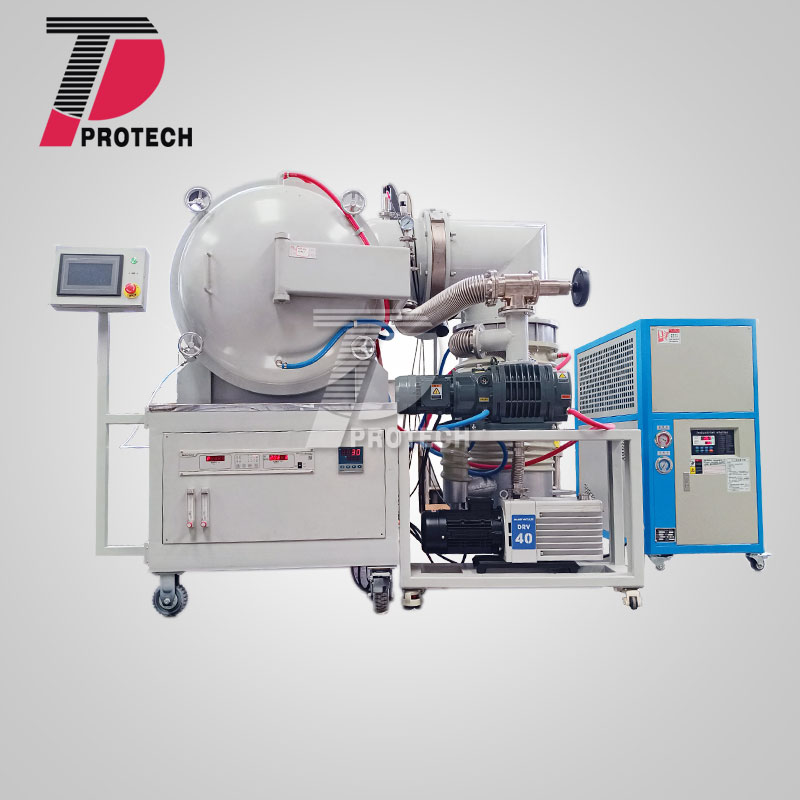

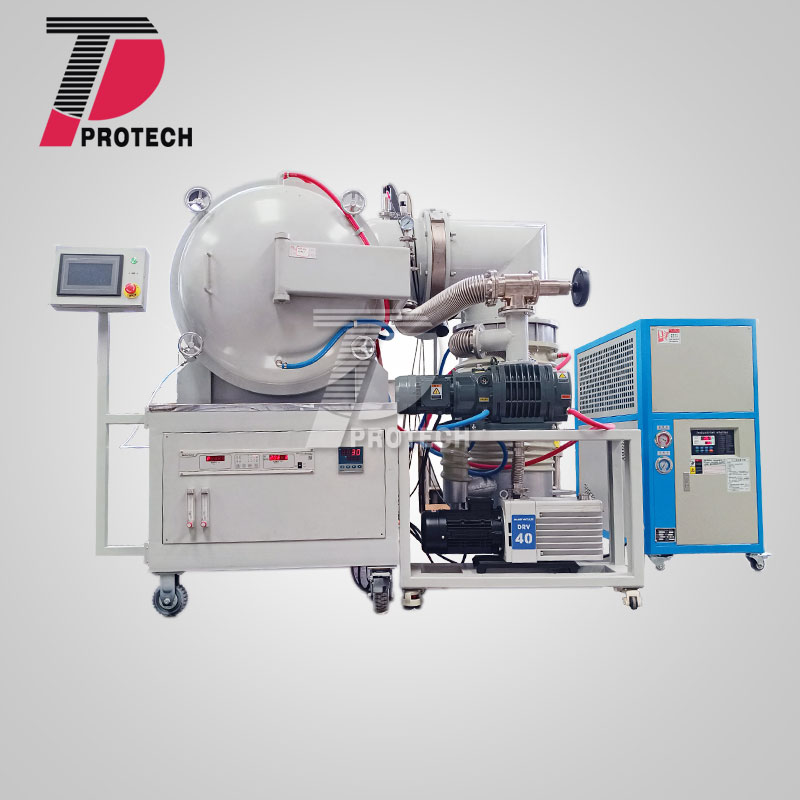

The PT-VX1200-36CWG vacuum furnace is a horizontal, single chamber structure, with a double layer water-cooled furnace body and furnace door, and a front door structure. Composed of furnace body, heating chamber, vacuum system, water cooling system, electric control and power supply system. Can perform vacuum brazing, vacuum sintering, and other vacuum heat treatments. Click to learn more about Vacuum Heat shield furnace.

| Name | 1200 ℃ Vacuum Heat Treatment Furnace Equipment | |||

| Model | PT-VX1200-36CWG | |||

| Structural type | horizontal single chamber structure | |||

| Power supply | 3-phase 380V, 50HZ | |||

| Effective furnace size | 300mm×300mm×400mm | |||

| Furnace material | alumina refractory fiber | |||

| Maximum heating temperature | 1200℃ | |||

| Normal working temperature | ≤1100℃ | |||

| Constant temperature accuracy | ±1℃ | |||

| Temperature control meter | Touch screen control and display of temperature | |||

| Heating rate | 10℃/min | |||

| Ultimate vacuum degree | 6.67* 10-3Pa(empty furnace, cold state, purified) | |||

| Vacuum unit | rotary vane pump+roots pump+diffusion pump unit | |||

| Gas flow | The furnace body is equipped with a reserved air inlet, which can flow various inert gases | |||

| Cooling method | The water cooler circulates cooling water to cool the furnace body and door | |||

| Control system | manual opening and closing of high vacuum valve | |||