0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

|

Model |

PT-V1400-64L |

||

|

Part I: Standard Parts heating |

|||

|

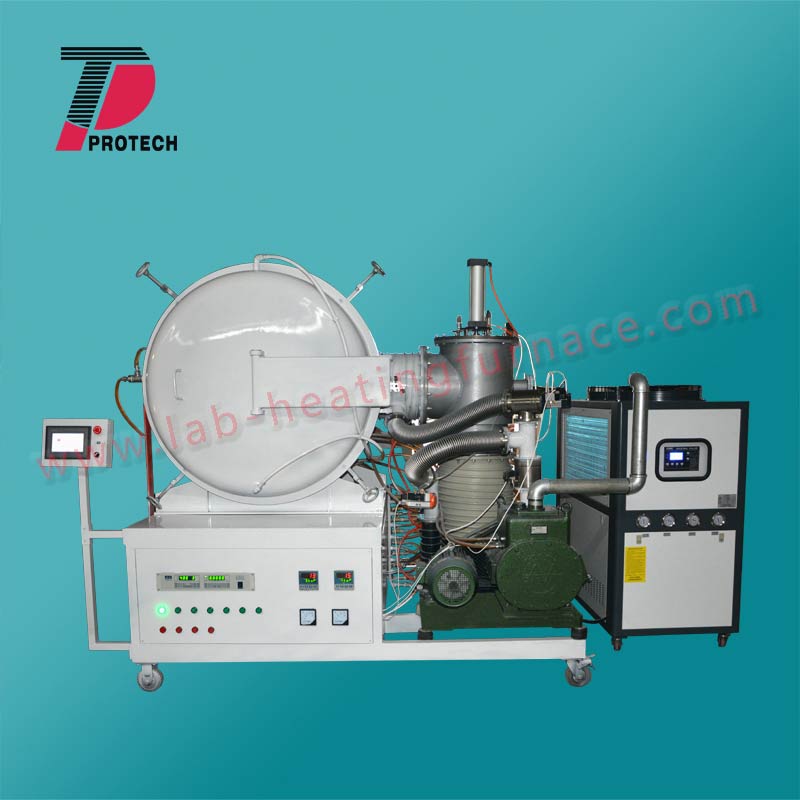

Heating Furnace

|

Furnace Feature |

Body structure: Double Layer steel casting support water jacket Furnace door inside is polished stainless steel Furnace shell: High intensity carbon steel with electrostatic spraying. Process using grinding mouth cavity seal sealing interface is stable and reliable New type chamber lining material.Low power consumption,energy saving and pro-environment. |

|

|

Display |

7” Touch Screen |

||

|

Max. Temperature |

1400℃ |

||

|

Continuous Working Temp. |

≤1300℃ |

||

|

Heating Rate |

0-10℃/min |

||

|

Heating Element |

Molybdenum belt |

||

|

Thermocouple |

S type |

||

|

Chamber Size |

400*400*400mm (Can be customized according to customer needs) |

||

|

Temperature Control |

PID automatic control via SCR power control |

||

|

Heating curves |

30 segment “time - temperature” curve adjustable and PID auto control Upper limited alarm and deviation alarm |

||

|

Part 2 Vacuum pump system |

|||

|

Vacuum Pump System

|

The vacuum system is made of one set Oil diffusion pump&.One set Rotary vane mechanical pump. Max. Vacuum degree of furnace chamber is 6.67x10-3Pa Ⅰ: Rotary Vane pump

Ⅱ: Dissusion pump

|

||