0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

Product Overview:

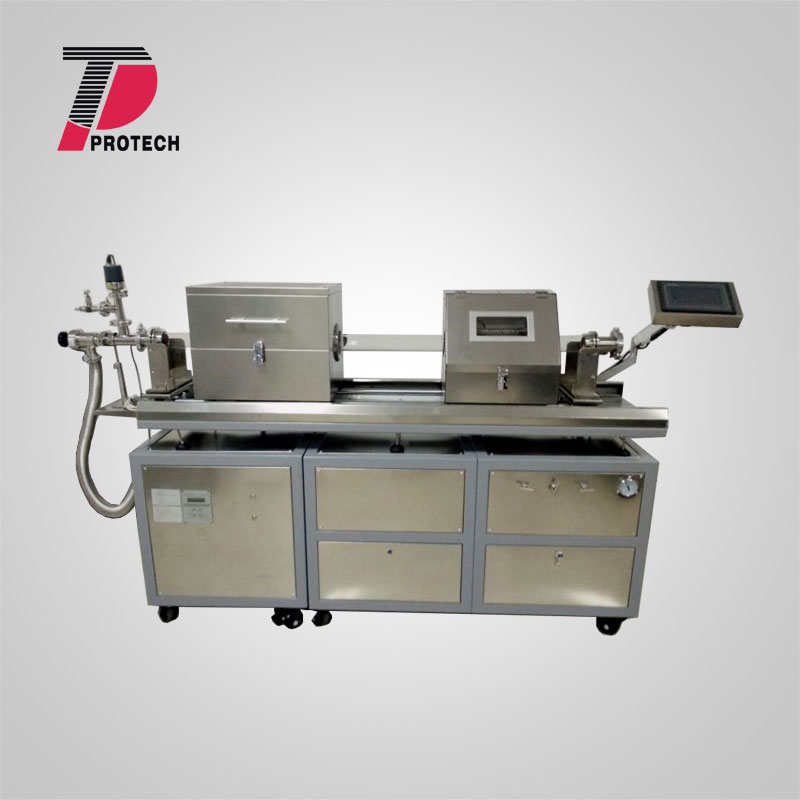

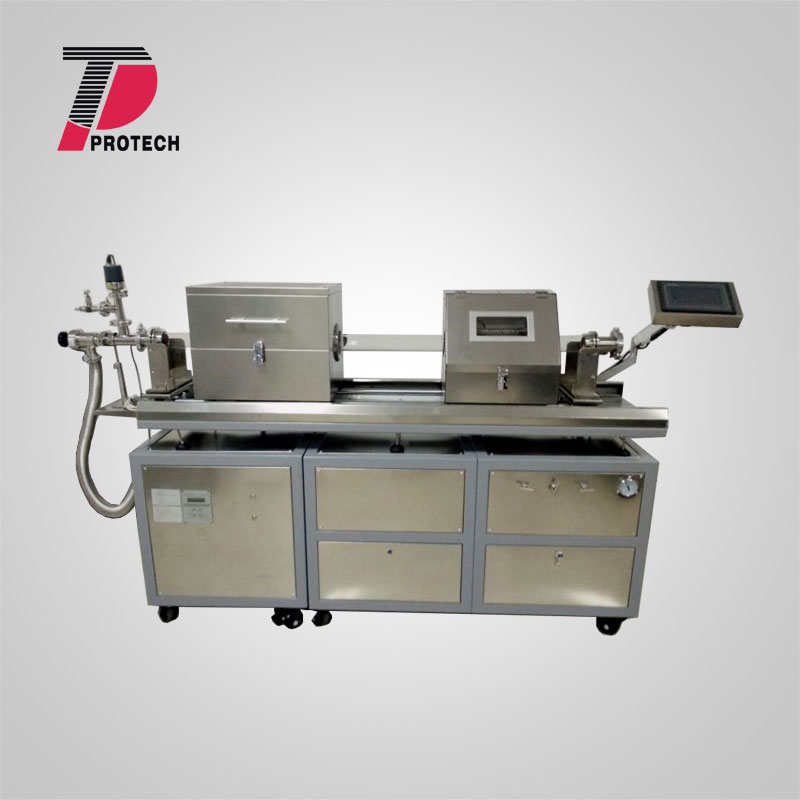

PT high vacuum PECVD system is composed of tube furnace, vacuum system, gas supply system, radio frequency power supply system, etc. The system is mainly used in the growth of metal thin films, ceramic thin films, composite thin films, graphene, etc. The PECVD system is easy to add functions and can expand the functions of plasma cleaning and etching. The PECVD system has the advantages of high film deposition rate, good uniformity, high consistency and stability.

Main Features:

1. Change the gas in the quartz vacuum chamber to an ion state through the radio frequency power supply.

2. PECVD requires a lower temperature than ordinary CVD for chemical vapor deposition.

3. The stress of the deposited film can be controlled by the frequency of the radio frequency power supply.

4. PECVD has higher chemical vapor deposition rate, better uniformity, consistency and stability than ordinary CVD.

5. Widely used in the growth of various thin films, such as SiOx, SiNx, SiOxNy and amorphous silicon (a-Si:H).

Technical Parameter:

|

product name |

High vacuum PECVD system |

|

Slide rail tube furnace part |

|

|

Product number |

PT-T1200 |

|

Furnace tube size |

Φ50mmX1600mm Customizable |

|

Furnace tube material |

Quartz tube |

|

Heating zone |

300mm Customizable |

|

Operating temperature |

≤ 1100°C |

|

Maximum temperature |

1200°C |

|

Temperature control method |

N-type thermocouple |

|

way to control |

Touch screen control, with independent rocker arm, you can adjust the angle of the temperature control screen according to actual needs, making it more convenient to use |

|

Temperature control accuracy |

±1℃ |

|

Temperature control protection |

With over-temperature and burnout protection function |

|

Heating rate |

0-20ºC/min, recommended 10ºC/min |

|

Heating element |

Molybdenum resistance wire |

|

Furnace material |

Alumina polycrystalline fiber |

|

Furnace structure |

The furnace body has a slide rail, which can realize rapid heating and cooling |

|

Flange joint |

Standard configuration is equipped with two stainless steel vacuum flanges, mechanical pressure gauge and stainless steel globe valve have been installed |

|

Sealing system |

The furnace tube and flange are extruded and sealed with a silica gel O-ring, which is convenient to remove and can be removed repeatedly, and has good air tightness. |

|

case |

Stainless steel housing |

|

Optional |

Auxiliary cooling fan |

|

Vacuum system part |

|

|

name |

Vacuum system |

|

The main parameters |

1. Using imported Agilent high vacuum molecular pump set, the ultimate vacuum degree can reach 10-3pa 2. KF25 quick connection, stainless steel bellows, manual flapper valve and flange, vacuum pump connection; 3. Digital vacuum display, its measuring range is 5×10-5-1500mbar, with high measuring accuracy |

|

Pneumatic system part |

|

|

name |

Four-way mass flow meter |

|

The main parameters |

Four-channel precision mass flow meter: touch screen control, digital display, automatic control. Flow range Flow range: 1. MFC 1-MFC4: 0-1000sccm adjustable 2. A mixing tank 3.4 stainless steel needle valves are installed on the left side of the gas supply system, which can manually control 4 kinds of gases; 4. Air inlet and outlet: 3 in and 1 out Flow control: manual rotary adjustment Connection mode: double card sleeve connection |

|

Plasma power supply part |

|

|

name |

500W plasma power supply |

|

Power range |

0-500W (continuously adjustable) |

|

working frequency |

13.56MHZ+0.005% |

|

Operating mode |

Continuous output |

|

RF output impedance interface |

N-type, female (50Ω) |

|

Power stability |

≤2W |

|

Maximum reflected power |

70W |

|

Power protection settings |

DC over current protection, power amplifier over temperature protection, reflected power protection |

|

Supply voltage/frequency |

Single-phase AC (187V-253V) 50-60HZ |

|

cooling method |

Wind cooling |