0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

| Technical parameter: | |

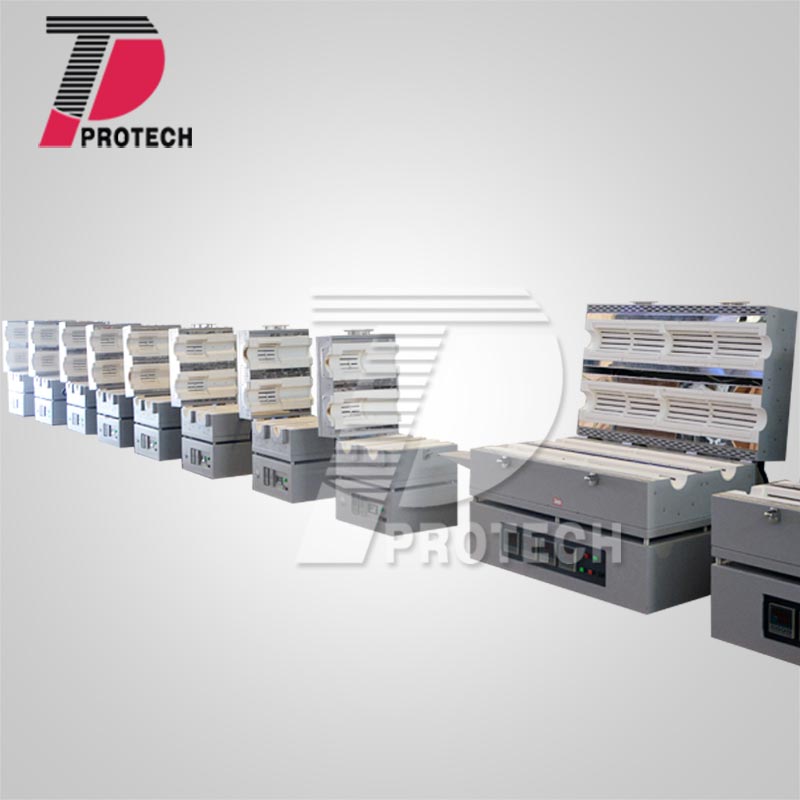

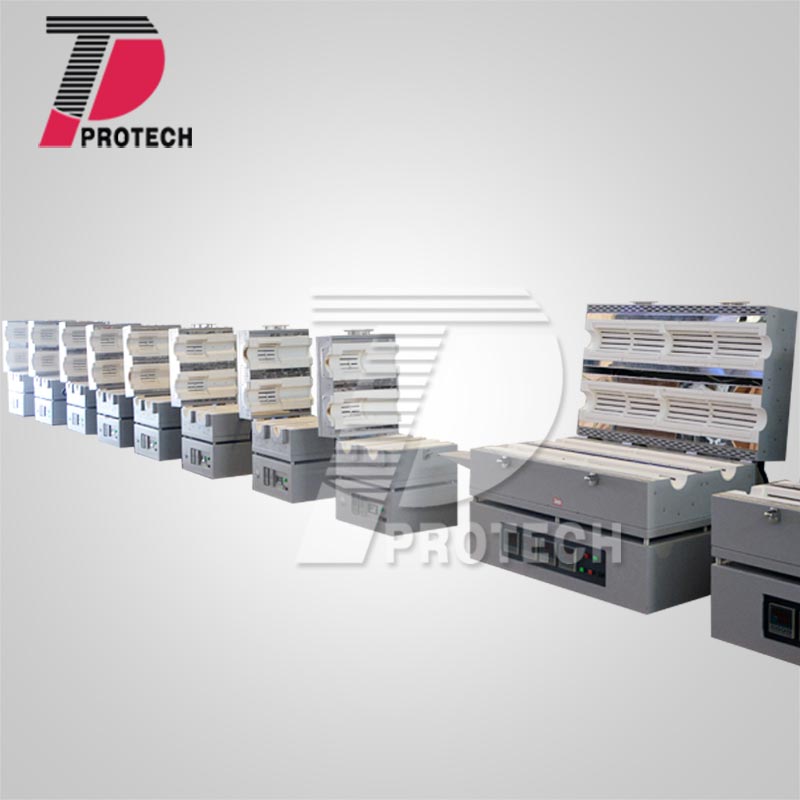

| Model | PT-T1200-S80 |

| Furnace structure | Double-layer shell structure, equipped with a cold air system to automatically cool down the furnace shell temperature does not exceed 50 ℃ |

| chamber size | High-quality high-purity alumina polycrystalline fiber curing furnace formed by Japanese technology vacuum adsorption has good thermal insulation performance, high reflectivity and balanced temperature field. |

| Max.temperature | 1200℃ |

| Continuous working temperature | 1100℃ |

| heating rate | Recommended ≤10℃/min, the fastest heating rate is 20℃/min |

| tube size | High Purity Quartz Tube |

| Heating zone length (double hearth) |

200mm (heating area) + 150mm (heat preservation area) |

| flange | Stainless steel sealing flange, easy to disassemble, one end is a common flange, one end is a hinge flange |

| Temperature Control System | The temperature control system adopts artificial intelligence adjustment technology, with PID adjustment and self-tuning functions, and can compile 30-stage heating and cooling programs; |

| Heating element | Molybdenum alloy resistance wire |

| Temperature measuring element | K-type thermocouple, independent temperature control of two temperature zones |

| Working power | AC220V,50Hz |

| rated power | 2.2KW |