0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

| Model | PT-T1200 | |

| Part I: Standard Parts | ||

| Tube Furnace |

Display | LCD/LED Touch Screen (Can be customized according to customer needs) |

| Max. Temp. | 1200℃ for short time | |

| Woking Temp. | ≤1100℃ | |

| Heating Rate | Suggestion: 0~10℃/min | |

| Temperature Zone | 440mm (Can be customized according to customer needs) | |

| Heating Element | Resistance wire with Mo | |

| Thermocouple | N type | |

| Temperature Control Accuracy | ±1℃ | |

| Tube Size | 100 x 1000mm (OD x minimum L) (Can be customized according to customer needs) | |

| Material: Quartz tube | ||

| Temperature Control | PID automatic control via SCR power control | |

| Heating curves | 30 steps programmable | |

| Vacuum Flange | Stainless Steel vacuum flange. One end of the flange has 1barbed needle valves, with installed Mechanical Pressure Gauge. Another end of the flange has a KF25 port with a barbed needle valve |

|

| Vacuum Pump | Rotary Vane Vacuum Pump | Ultimate vacuum 10-3 Torr. Vacuum inside the tube is around 10-1 Torr. (RM temp. And empty tube condition) Flow rate: 2L/S The rotary vane vacuum pump will be designed into a cart with wheel. With connection accessories Digital vacuum gauge is included |

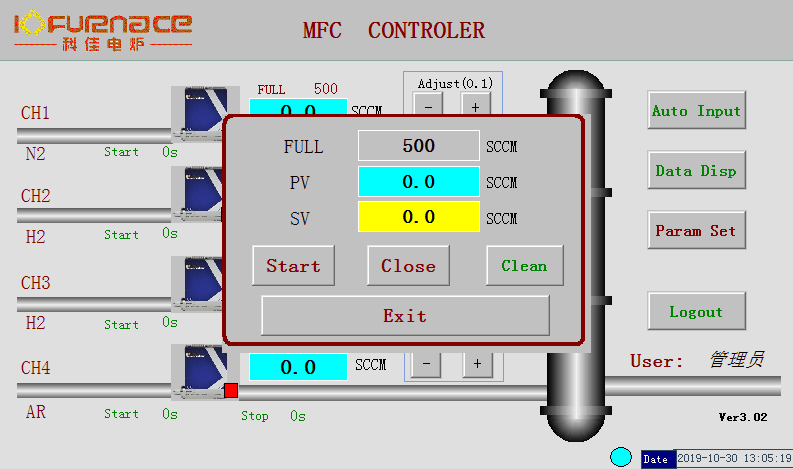

| Mass Flow Meters (Seven Star Brand) With LCD Touch Screen Controller (Desigen by Kejia with Kejia logo) |

One Float flowmeter + Five precision mass flow meters : MFC Accuracy is: ±1.5% F.S. MFC 1 for nitrogen : Gas flow range from 0~100 sccm MFC 2 for hydrogen : Gas flow range from 0~200 sccm MFC 3 for methan : Gas flow range from 0~300 sccm MFC 4 for argon: Gas flow range from 0~400 sccm MFC 5 for oxygen: Gas flow range from 0~500 sccm One gas mixing tank (for 5 MFC only) is installed on bottom case with 4 stainless steel needle valves is installed on left side of bottom case to control 4 type gases mixing manually.   |

|