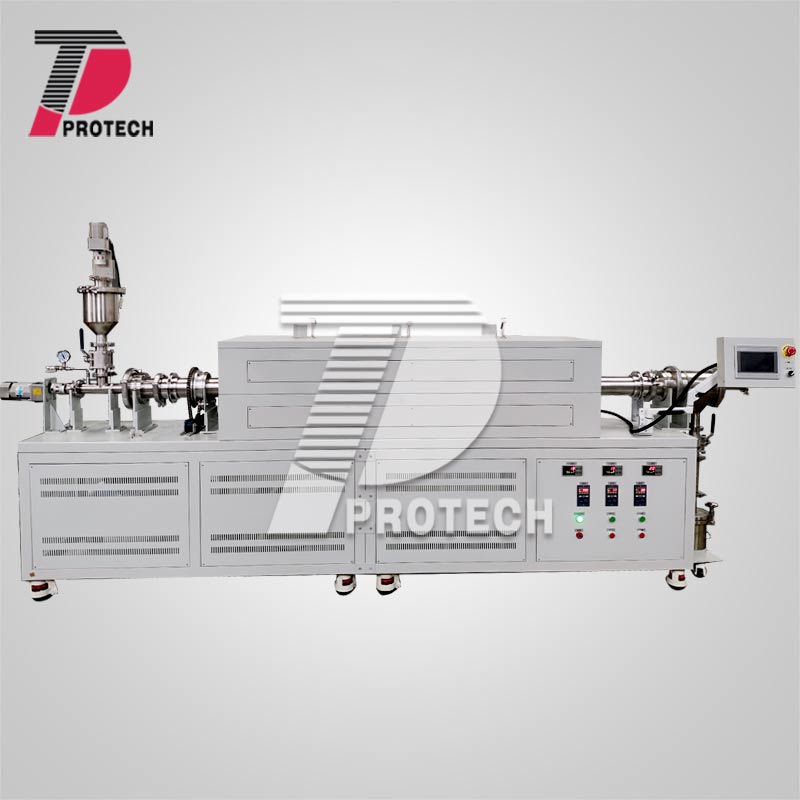

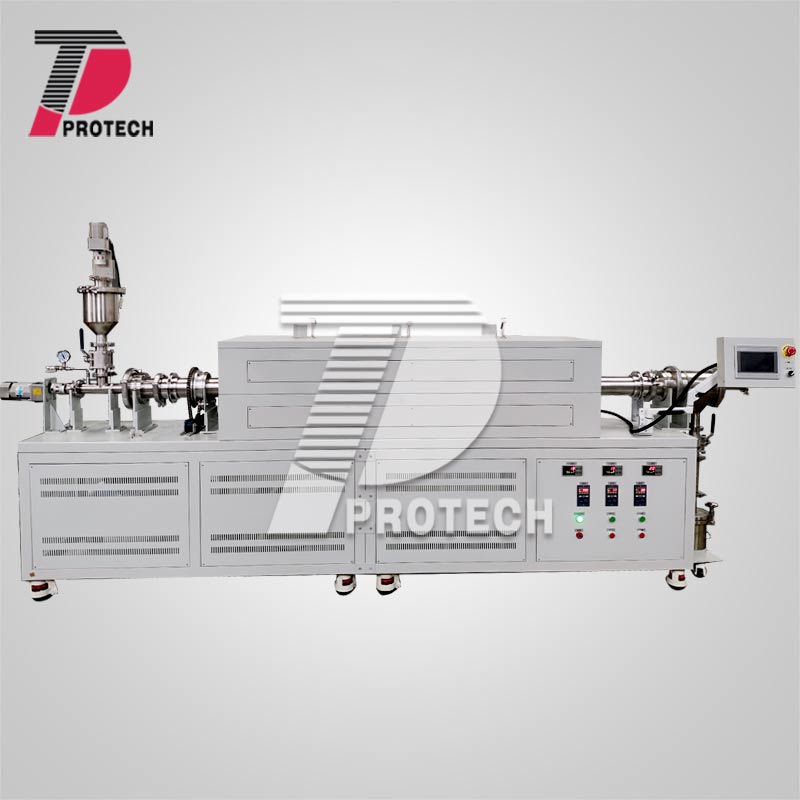

model:PT-TX1400-S150LK3WQ

Rotary Tube Furnace With Automatic Feeding & Receiving System

Application: The tilted rotary tube furnace adopts three temperature zones with independent heating control, and a multi-stage program temperature control system for each zone. The touch screen operation can store multiple sintering processes and the sintering data can be recorded and exported.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Product description:EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacThe tilted rotary tube furnace consists of a heating system, a control system, a feeding system, a receiving system, and an exhaust gas treatment device.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The tilted rotary tube furnace adopts three temperature zones with independent heating control, and a multi-stage program temperature control system for each zone. The touch screen operation can store multiple sintering processes and the sintering data can be recorded and exported.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The furnace body is a double-shell air-cooled structure, and the upper opening type is convenient for cooling and heat dissipation and replacement of furnace tubes, and has a tilting function.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The furnace tube adopts corrosion-resistant high-purity quartz tubes, and the tube is equipped with a lifting plate. The furnace tube has a forward and reverse function and an adjustable speed.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The feeding and receiving materials use a 316L material feeding bin.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The furnace chamber is made of alumina polycrystalline fiber material, high-quality silicon carbon rod heating, circular arrangement of temperature field balance, and an air cooling system between the double-layer furnace shells.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Three temperature zone rotary tilt tube furnace(Automatic loading and unloading)

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacFeatures:EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacEgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacThe rotating motion of the furnace tube causes the materials to be constantly turned and mixed in the furnace, avoiding the problems of material accumulation and local overheating, ensuring that the materials are heated evenly, thereby improving the consiEgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

It can process materials in various forms, such as powders, granules, bulk solids, etc., and is suitable for heating, sintering, synthesis and other processes of various materials, including ceramics, metals, semiconductors, catalysts and other material fEgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

PID automatic control and thyristor adjustment can accurately control the temperature in the furnace, achieve a stable heating process, improve heating quality, and ensure the reliability and repeatability of product performance.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

It is equipped with an over-temperature alarm device, and the electric heating element is equipped with an ammeter and a voltmeter, and has power-on interlock protection and safety grounding measures, as well as overload and short-circuit protection measure.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

A computer interface is reserved to realize interconnection with the computer, and can record and store data such as heating, insulation and cooling curves, which is conducive to optimizing process parameters and improving product quality.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

According to different material characteristics, processing requirements, production scale and other factors, the furnace size, furnace tube material, number of temperature zones and other parameters can be customized.EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacEgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacEgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacTechnical parameters:

| Model |

PT-TX1400-S150LK3WQ |

| Shell structure |

Double-layer shell. Equipped with air cooling system |

| Tube size |

Outer diameter 100mm*length about 2200mm (Can be customized according to customer needs) |

| Furnace tube |

High-purity customized quartz tube |

| Sealing structure |

Relative sealing |

| Air inlet |

1-way air inlet |

| Air outlet |

1 exhaust port |

| Number of temperature zones |

3 temperature zones |

| Temperature zone length |

Total length is 1500mm (Can be customized according to customer needs) |

| Working temperature |

The temperature is not more than 1300℃ under continuous operation; limit temperature: 1400℃ |

| Temperature control method |

Adopt intelligent 30-segment programmable control |

| Ultra-high temperature alarm |

There is ultra-high temperature alarm |

| Broken couple prompt |

There is broken couple prompt |

| Chamber material |

High-purity alumina refractory fiber |

| Heating rate |

0--10℃/min |

| Furnace door structure |

Top opening type |

| Heating element |

High-quality silicon carbon rod |

| Tilt angle |

0-10 degrees (adjustable) |

| Furnace tube speed |

0.5-1 rpm (adjustable) |

| Feeding |

The feeding bin is made of 316L material. The feeding speed is adjustable and has the function of electric stirring. |

| Collection |

The collecting bin is made of 316L material |

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacThe following are other customized two-temperature zone continuous feeding and discharging rotary tube furnaces:

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacTitanium tube type-Continuous feeding and discharging rotary tube furnaces

EgIMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacTitanium tube type-Continuous feeding and discharging rotary tube furnaces