0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

The main applications of the large diameter stainless steel rotary tube furnace include high-temperature sintering of materials such as graphite, sodium titanium phosphate, molecular sieves (PSA molecular sieves), carbon nanotubes, chemical vapor deposition (CVD carbon coating), CVD carbon pore adjustment, and other sintering equipment required for the process. It can pass the atmosphere or vacuum. This furnace has several major advantages, such as high efficiency, energy conservation and environmental protection, high technological content, and strong practicality. Click to learn more about Inclined rotary tube furnace!

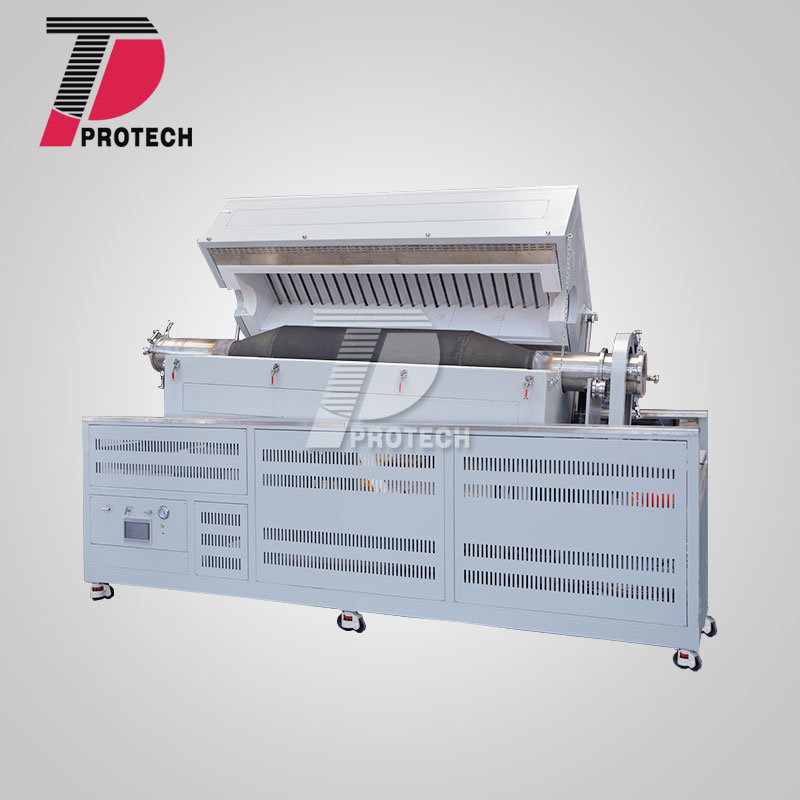

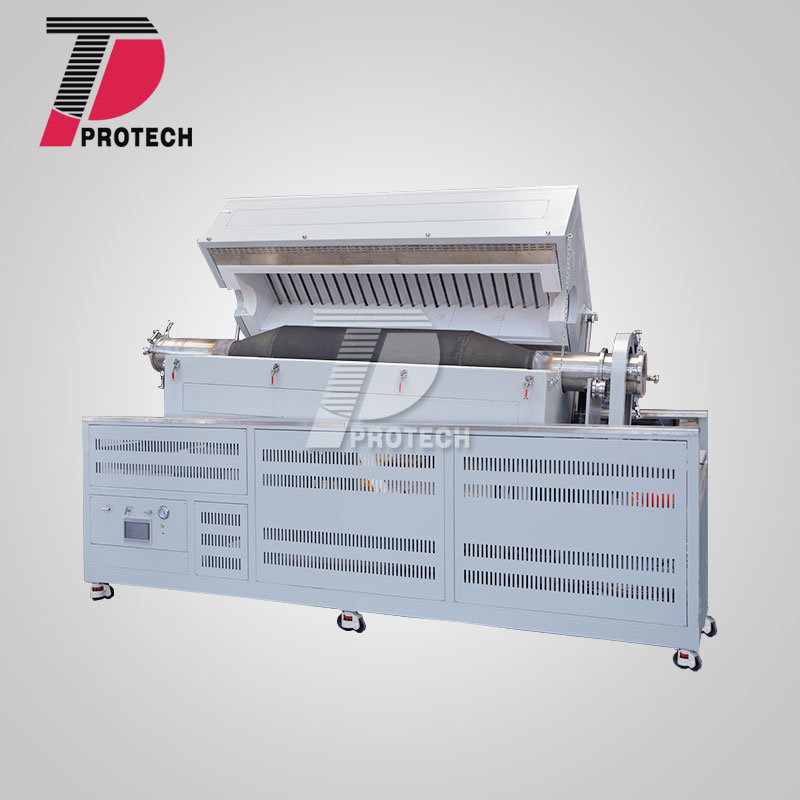

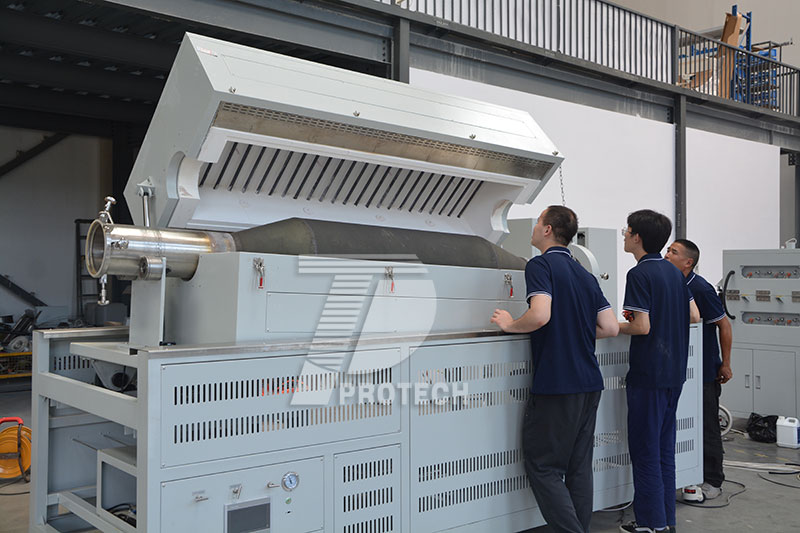

Actual photo of large diameter stainless steel rotary tube furnace

This equipment consists of a rotary heating furnace (with an electric flip device), furnace tubes, electrical control, vacuum system, etc.

1. The rotary heating furnace is composed of a furnace shell, furnace lining, heating element, and furnace tube rotating device. The furnace shell is divided into upper and lower parts, and the upper part is electrically controlled. It can be flipped and opened when loading and unloading the furnace tubes. The furnace lining adopts alumina fiber lining. The heating element is installed on the furnace lining using high-temperature silicon carbon rods. The furnace tube rotation device adopts frequency conversion speed control drive, and the rotation speed can be arbitrarily set within a certain range.

2. The furnace tube is a circular stainless steel variable diameter tube, which adopts a structure with thin ends and thick middle to ensure sufficient reaction of the material in the middle heating part. The pouring of the product can be electrically controlled by tilting angle. The furnace tube can rotate clockwise or counterclockwise, and the rotation speed can be adjusted within a certain range. Users can determine the appropriate rotation speed based on the shape, material, and temperature of the processed product under high temperature conditions. The furnace tube material is SUS310S stainless steel, and there is a lifting plate inside the tube, which can lift the material during the rotation process and receive heat evenly. Sealing flanges are used at both ends of the furnace tube, and a rotating joint is installed at the inlet end to allow for air circulation. Materials enter and exit from the inlet end.

3. Temperature control system: This furnace is equipped with an automatic temperature control system and PID automatic power regulation control, which can automatically adjust the input of current. The temperature control instrument adopts a programmable intelligent instrument, which can set the heating curve in sections. The control execution system adopts thyristor control and is equipped with air switches and fast fuses for secondary protection, with overload, short circuit and other protective measures. It is also equipped with air switches and fast fuses for secondary protection, with overload, short circuit and other protective measures to reliably ensure the normal operation of the control components.

4. Safety measures: Equipped with an over temperature alarm device. The electric heating element is equipped with an ammeter, a voltmeter, and power on interlocking protection and safety grounding measures to ensure safe use.

5. Vacuum system: Adopting magnetic fluid sealing to ensure normal vacuum pumping during furnace tube rotation. The vacuum pump adopts a rotary vane pump with a pumping speed of 8L/S. By turning on the vacuum pump switch, vacuum can be pumped.

6. Flowmeter: The mass flow meter accurately controls the flow rate and can pass through inert gases such as nitrogen.

Actual photo of large diameter stainless steel rotary tube furnace

| Product name | Large diameter rotary tube furnace | ||

| Product model | PT-TX1000-H400LK4 | ||

| Maximum temperature | 1000℃ | ||

| Number of heating zones | 4 zones | ||

| Temperature control accuracy | ±1℃ | ||

| Temperature control meter | 30 segment programmable PID intelligent control, phase shift triggering | ||

| Dimensions of furnace chamber | φ400×1500mm (Can be customized according to customer needs) | ||

| Temperature measuring element | 4 N-type thermocouples | ||

| Heating element | silicon carbide rod | ||

| Heating zone size | 1500mm (Can be customized according to customer needs) | ||

| Charging capacity | effective volume is about 180L (about one-third of each discharge)-- ½) (Can be customized according to customer needs) |

||

| Furnace tube material | 310S variable diameter tube | ||

| Furnace tube size | middle φ 400 rpm at both ends φ 200mm (Can be customized according to customer needs) |

||

| Furnace lining material | alumina polycrystalline fiber | ||

| Sealing method | stainless steel sealing flanges at both ends for easy disassembly | ||

| Tilt angle | furnace tube rotates 360 degrees 0-15 degrees (angle adjustable) Rotation speed -0-5 revolutions (adjustable speed) | ||

| Rotation speed | 0-5 revolutions (adjustable speed) | ||

| Vacuum sealing | rotating sealing structure | ||

| Vacuum pump | rotary vane pump (8L/S) pre pumping vacuum | ||

| Furnace structure | carbon steel spray molding, open furnace door | ||

| Furnace door opening | electric opening | ||

| Flow meter | mass flow meter, inert gases such as nitrogen | ||

Actual photo of large diameter stainless steel rotary tube furnace