0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

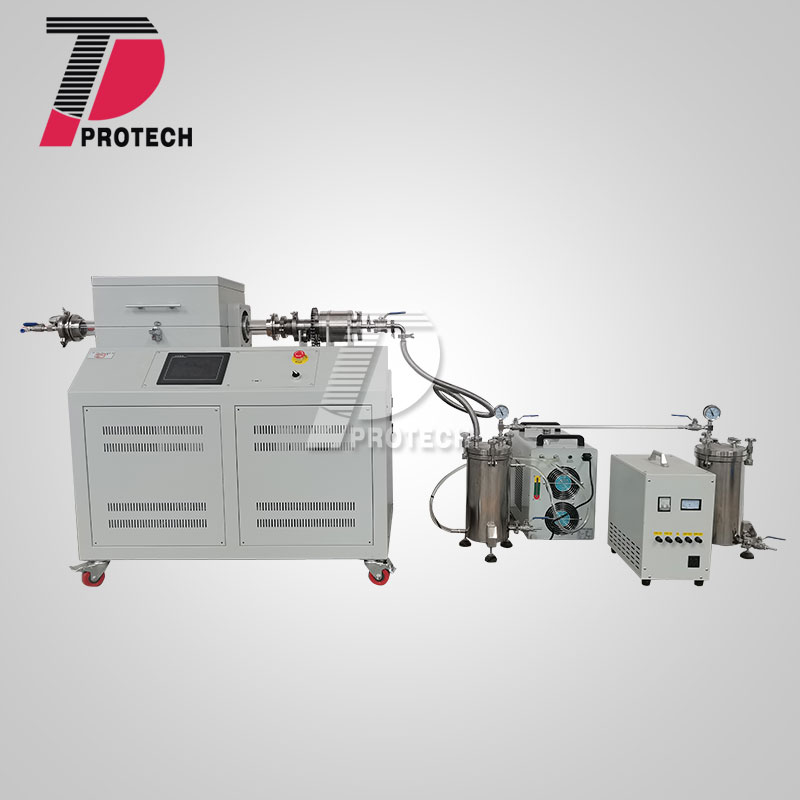

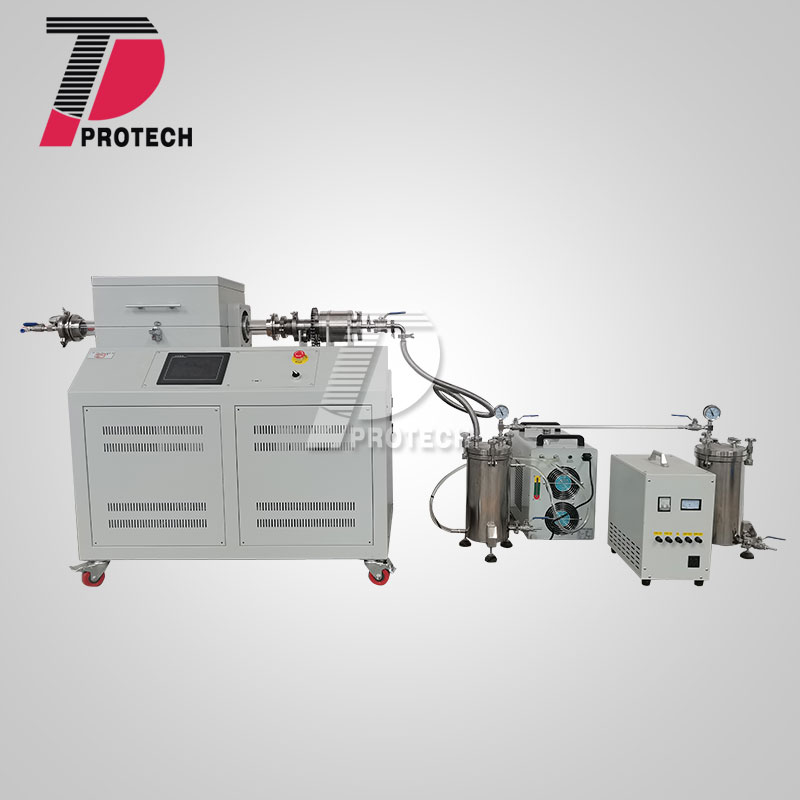

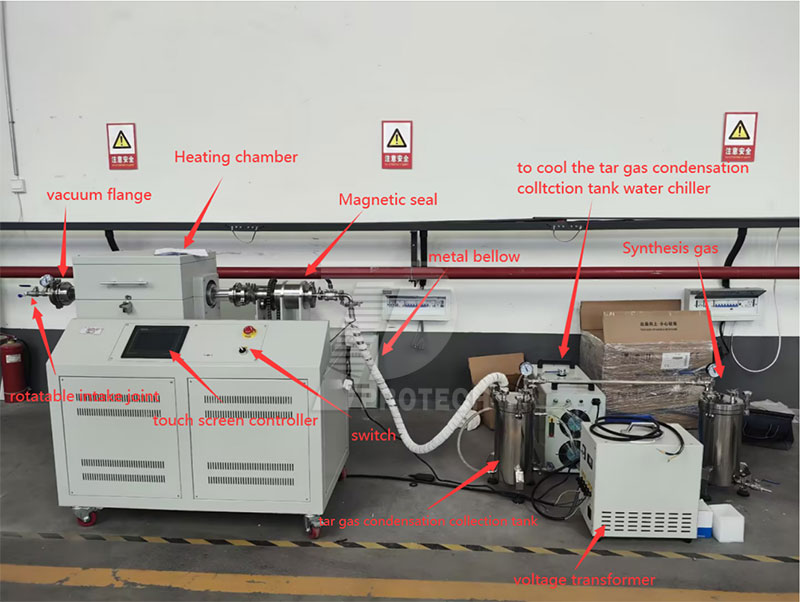

The PT-TX1100-S60CK1W biomass pyrolysis furnace is mainly used for laboratory biomass pyrolysis experiments. The entire equipment includes a pyrolysis furnace, tar gas condensation collection tank, and synthesis gas collection tank. There is a gas outlet in the gas collection tank for easy connection to the gas analyzer for gas composition analysis experiments of synthetic gas. It belongs to a type of inclined rotary tube furnace.

Illustration of PT-TX100-S60CK1W Biomass Pyrolysis Furnace

| Biomass cracking furnace | |

| Model | PT-TX1100-S60CK1W |

| Control system | LCD touch screen (LED Can be customized according to customer needs) |

| Working temperature | ≤1100℃ |

| Heating rate | 0-20 ℃/min, recommended ≤ 10 ℃/min |

| Heating area size | large belly quartz tube Middle outer diameter 100mm; Outer diameter of both ends 60mm (Can be customized according to customer needs) |

| Furnace tube material | High purity quartz tube |

| Heating element | containing molybdenum resistance wire |

| Furnace tube speed | 0-10 RPM |

| Furnace tube inclination angle | 0~30° |

| Thermocouple | N-type |

| Temperature control | intelligent PID program automatic temperature control |

| Temperature control | intelligent PID program for automatic temperature control Heating curve -16 temperature curves can be set, each temperature curve can be automatically set, and 30 steps of programming can be achieved. |

| Furnace material | alumina fiber |

| Rotable intake connector | convenient for gas admission |

| Connect the metal corrugated pipe of the pyrolysis furnace to the condensate tank: | wrap it with a heating tape to prevent the synthesis gas from cooling before entering the condensate tank. |

| Tar gas collection | Tar gas condensation collection tank; Equipped with a chiller unit for cooling gas |

| Syngas collection tank | Collect syngas for sampling and analysis |

| Warranty | One year warranty period (consumables such as quartz tubes are not covered by the warranty) |

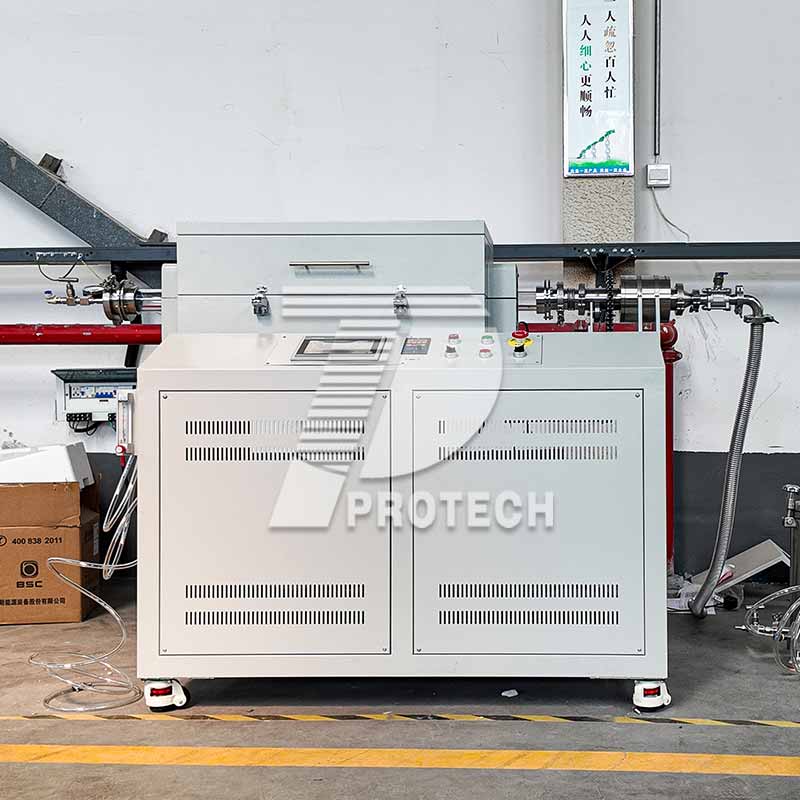

Actual photo of PT-TX100-S60CK1W biomass pyrolysis furnace