0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

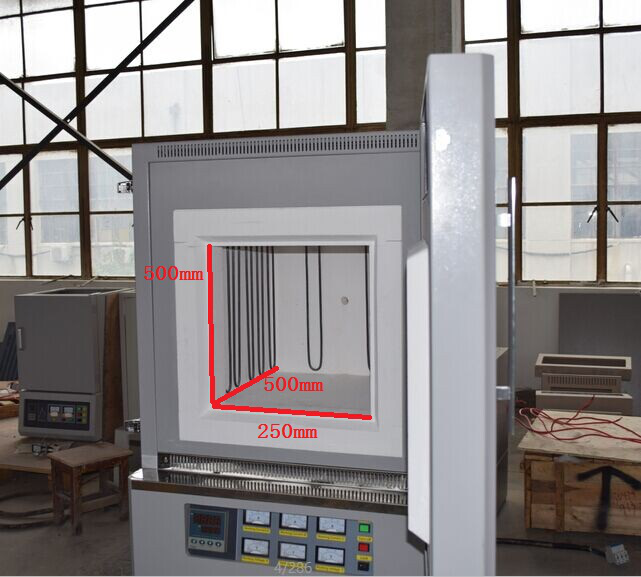

| Model | PT-M1600-63L |

| Picture |

|

| Furnace structure | Double layer steel casing with dual cooling fan, temperature of furnace shell below 60deg.C. |

| Furnace liner |

Two layers of ceramic fiber insulation materials First layer: 1800deg.C ceramic fiber board Second layer: 1600deg.C ceramic fiber board |

| Chamber dimension |

500 X 250 X 500mm |

| Working temperature | 1600℃ |

| Heating rate | 0-25℃/min (Suggestion: 0-10℃/min) |

| Temp. accuracy | +/-1℃ |

| Thermocouple | B-type thermocouple |

| Temp. control |

PID automatic control via SCR (Silicon controlled rectifier) Power control with phase angle fired, current limiting resistor 30 programmable segments for precise control Bulit-in PID auto-tuned function with overheating & broken thermocouple broken protection. Over temperature protection and alarm allows for operation without attendant |

| Heating element | MoSi2 heating rods |

| Working voltage | 220V, 50/60Hz, Single phase(Customized) |

| Power | 20 kW |

| Production period | 15 working days |

| Warranty Period | 1 year (Consumable uncovered.) |

| Other | Can be custom base on your require |

|

crucible tong 1 pair |

|

High temperature refractory gloves 1 pair |

|

Allen key 1 piece |

|

2 heating rods |

Duis aute irure dolor in repreh enderit in volup tate velit esse

cillum dolore

eu fugiat nulla dolor atur with Lorem ipsum is simply