0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

PT-A1600-64CZ series high-temperature atmosphere furnace adopts a double-layer shell structure and an intelligent program temperature control system, with phase shift trigger and thyristor control. The furnace is made of alumina polycrystalline fiber material. The double-layer furnace shell is equipped with an air cooling system.Belongs to a type of atmosphere furnace.

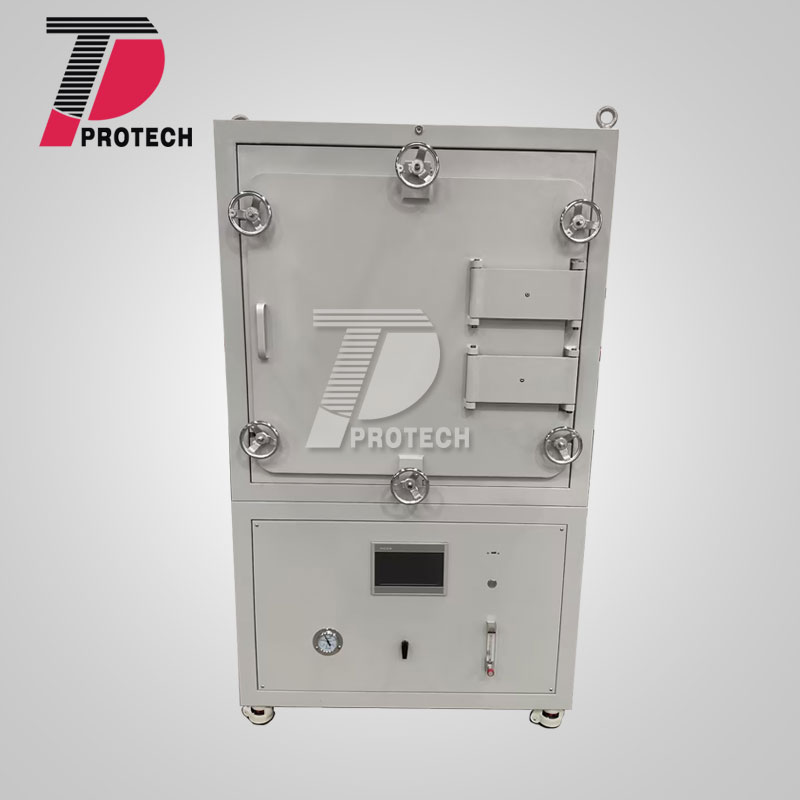

Real shot of 1600 ℃ high temperature atmosphere furnace

The PT-A1600-64CZ series high-temperature atmosphere furnace adopts a double-layer shell structure and an intelligent program temperature control system, with phase shift trigger and thyristor control. The furnace is made of alumina polycrystalline fiber material. The double-layer furnace shell is equipped with an air cooling system.

1. Low surface temperature, fast temperature rise and fall, energy-saving.

2. High quality aluminum oxide polycrystalline fiber inorganic material formed by vacuum adsorption using Japanese technology has good insulation performance, durability, high tensile strength, no foreign particles, high purity, and significantly better energy-saving effect than other fiber materials.

3. The entire furnace body adopts a double-layer lining structure with an air gap in the middle. Even if the furnace temperature reaches its maximum, the surface of the furnace body can still be safely touched without any burning sensation.

4. The electric furnace adopts energy-saving materials, and the overall energy consumption is only one-third of that of traditional electric furnaces, which is energy-saving and environmentally friendly.

5. The furnace body is equipped with an output voltage and output current monitoring meter, and the heating status of the furnace is clear at a glance.

6. Over temperature alarm and power outage function and leakage protection measures ensure safe and reliable operation.

| Product Name | 1600 ℃ high-temperature atmosphere furnace |

| Product model | PT-A1600-64CZ |

| Door opening method | Side door opening |

| Furnace structure | Double layer steel casting with dual cooling fans |

| Display method | touch screen |

| Maximum temperature | 1700℃ |

| Continuous working temperature | ≤1600℃ |

| Furnace material | alumina fiber |

| Heating rate | recommended 0-5 ℃/min |

| Accuracy | ±1℃ |

| Internal chamber size (width * height * depth) | 400x400x400mm |

| Capacity | 64L |

| Heating element | MoSi2 |

| Thermocouple | Type B |

| Temperature control | ● PID automatic control through SCR (silicon controlled rectifier) power control, phase angle triggering, and current limiting resistor. 30 programmable segments for precise control of heating rate, cooling rate, and residence time. Built in PID automatic adjustment function, with protection for overheating and thermocouple disconnection. ● Overtemperature protection and alarm allow for unmanned operation. |

| Sealing system | The furnace door is sealed with high-temperature silicone rubber and sealing valve |

| Gas supply system | Gas inlet and outlet are equipped with shut-off valves, which can transport nitrogen and other gases to the furnace |

| Output power | 27KW |

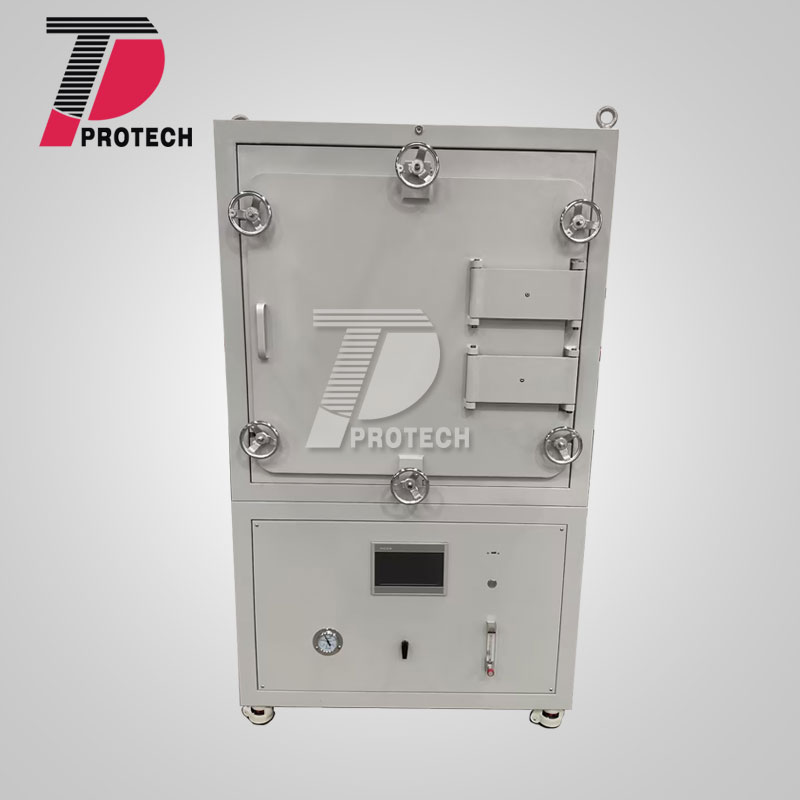

Real shot of 1600 ℃ high temperature atmosphere furnace