0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

PT-A1300-16CZ Series high temperature atmosphere furnace is mainly used in college laboratories, industrial and mining enterprise laboratories, for chemical analysis, physical measurement and sintering and dissolution of metals, ceramics, etc., used in electronic components, powder metallurgy, magnetic materials, quartz materials and other products It can also be used for heat treatment of other materials etc. The furnace body adopts a double-layer furnace shell structure, high-performance heat insulation material, and is equipped with a cooling fan, so that the surface temperature of the furnace body is low, and the energy saving is 60% compared with ordinary furnaces. The furnace door and furnace top are sealed with high-temperature silicone rubber, which can be pre-evacuated and can be fed with various inert gases.Belongs to a type of atmosphere furnace.

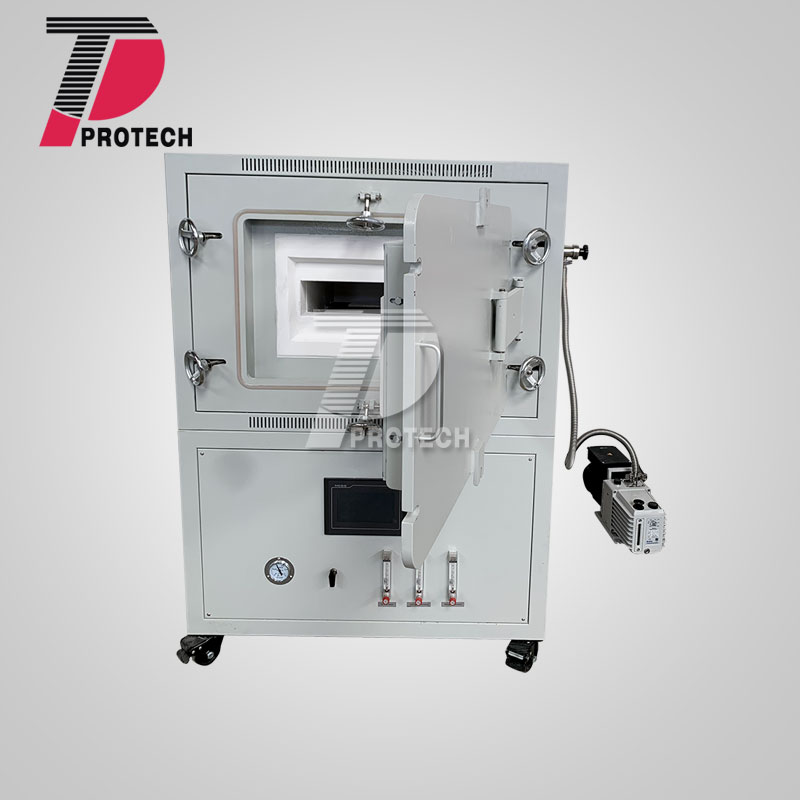

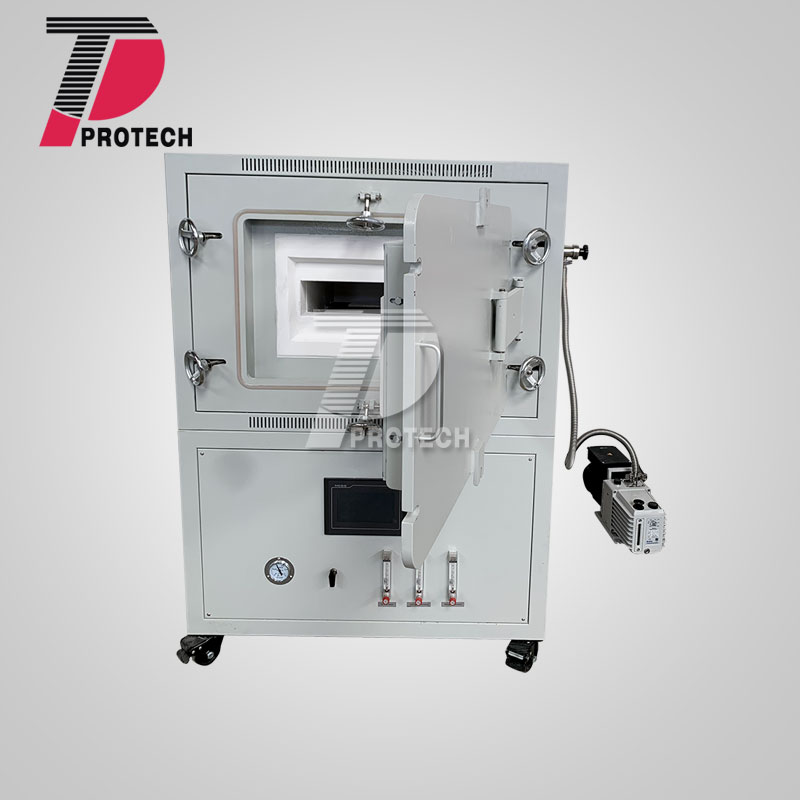

Actual photo of 1400 ℃ high-temperature atmosphere furnace

PT-A1300-16CZ Series high temperature atmosphere furnace adopts double-layer shell structure and intelligent program temperature control system, phase-shift trigger and thyristor control. The furnace is made of alumina polycrystalline fiber material. The double-layer furnace shell is equipped with an air-cooling system. It has the advantages of low surface temperature, fast temperature rises and fall rate, and energy saving.

Actual photo of 1400 ℃ high-temperature atmosphere furnace

1.The furnace adopts high-quality alumina polycrystalline fiber inorganic material formed by vacuum adsorption with Japanese technology, which has good thermal insulation performance, durability, high tensile strength, no foreign balls, high purity, and energy saving effect is obviously better than other fiber materials;

2.The entire furnace body adopts a double-layer liner structure with an air gap in the middle. Even if the furnace temperature reaches the highest, the surface of the furnace body can still be safely touched without a burning feeling.

3.The furnace is made of energy-saving materials, and the energy consumption of the whole machine is only 1/3 of the same traditional electric furnace, which is energy-saving and environmentally friendly.

4.The furnace body is equipped with: output voltage and output current monitoring table, the heating state of the furnace is clear at a glance.

5.Over-temperature alarm power-off function and leakage protection measures, safe and reliable operation.

| Door Structure | Side Door | |

| Furnace structure | Double layer steel casting with dual cooling fan | |

| Display | Touch Screen | |

| Max. Temperature | 1400℃ | |

| Continuous working Temperature | ≤1300℃ | |

| Chamber Material | Alumina fiber | |

| Heating Rate | Suggest 0-5℃/min | |

| Accuracy | ±1℃ | |

| Inside Chamber Size (Width*Height*Depth) |

400x100x400mm Customizable | |

| Volume | 16L | |

| Heating Element | SIC ROD | |

| Thermocouple | S Type | |

| Temperature control |

● PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle fired, current limiting resistor. ● 30 programmable segments for precise control of heating rate, cooling rate and dwell time. ● Built in PID Auto-Tune function with overheating & broken thermocouple broken protection. ● Over temperature protection and alarm allows for operation without attendant. |

|

| Sealing system | Furnace door use high temperature silicone rubber seal and seal valves | |

| Gas system | Gas inlet and outlet with shut off valve, can pass nitrogen and other gases to the furnace chamber;  Standard equipped with 3 float flow meters. |

|

| Vacuum Pump |  |

Pumping speed: 4L/s Including the connection to the furnace. Vacuum level: -0.1mpa |

| Warranty | One-year limited warranty, provide life-time maintenance service. (Consumable parts such as heating elements and thermocouple are not covered by the warranty) | |