Graphite vacuum furnace is a kind of equipment that plays an important role in specific fields. Taking the vacuum carbon tube resistance furnace as an example, it is a high-temperature, high-vacuum resistance furnace that uses graphite as the heating element. It is composed of a furnace cover, a furnace body, a furnace bottom and a vacuum unit. The inner layer of the furnace shell is stainless steel, and the outer layer is carbon steel. The two layers are cooled by water. The furnace shell is equipped with exhaust ports, observation holes, thermocouple holes, protective atmosphere inlets and outlets, explosion-proof ports, etc. The furnace is equipped with graphite electrodes, which are connected to the graphite heating element by cylindrical contact. There is a heat insulation screen device composed of multiple layers of radiation screens around the heating element. The following is an analysis of its technical advantages from three dimensions:Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac1. Core material: the "three highs" characteristics of graphiteY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacHigh temperature resistanceY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The melting point of graphite is as high as 3850℃, and the structure is stable at high temperature, supporting the long-term operation of the furnace above 2000℃ (such as sapphire crystal growth requires an environment of 1900-2200℃).Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

High efficiency of thermal conductivityY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The thermal conductivity is 1.5 times that of steel. With the vacuum environment (≤6×10⁻³Pa), heat can be evenly transferred to the workpiece to avoid local overheating.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Chemical corrosion resistanceY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Strong corrosion resistance to acids, alkalis and molten metals, ensuring pollution-free treatment of high-purity materials (such as semiconductor silicon wafers).Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac2. Core structure: modular design adapts to multiple scenariosY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacHeating systemY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

a. Heating element: graphite rod/tube/plate, customizable multi-zone layout (such as spiral, mesh), achieving ±1℃ precise temperature control.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

b. Support parts: graphite bracket, connecting rod, bolt, etc., impact-resistant and reduce heat loss.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Vacuum systemY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Mechanical pump + diffusion pump combination vacuum to prevent material oxidation (such as titanium alloy sintering requires an oxygen-free environment.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Intelligent controlY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

51-segment programming curve automatic heating/insulation/cooling, infrared temperature measurement + tungsten-rhenium thermocouple dual redundant monitoring.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

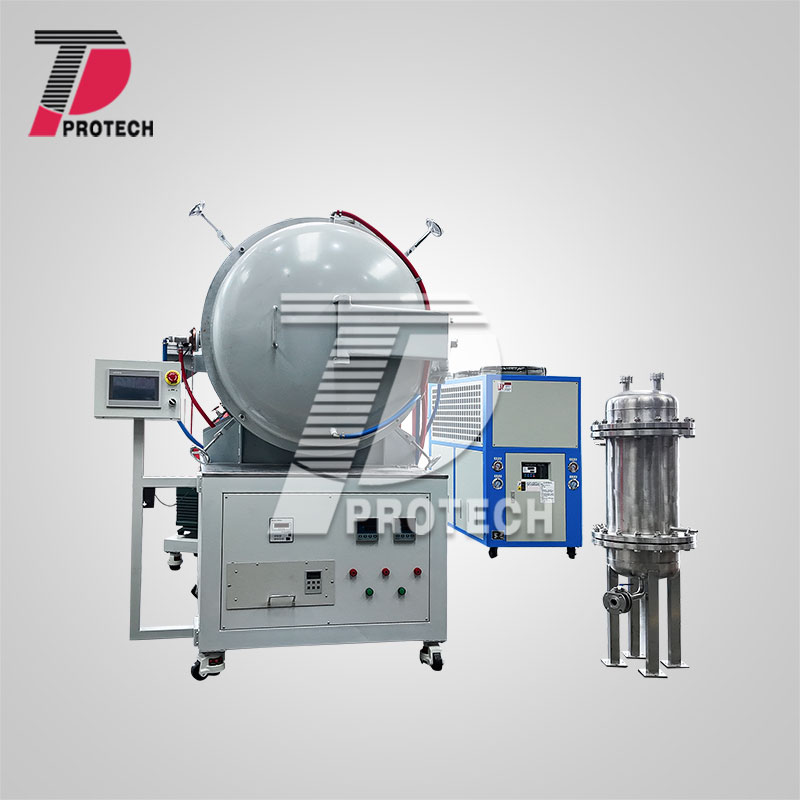

Graphite vacuum furnaceY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

click the picture to learn more

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Silicon carbide reinforced graphite parts (improve wear resistance), ceramic-based composite material sintering.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Semiconductor manufacturingY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Wafer annealing, gallium arsenide single crystal growth (depending on 2200℃ uniform thermal field).Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Precision component processingY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Aerospace alloy brazing (such as titanium aluminum blade connection), cemented carbide debonding Fat sintering.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac4. Operational advantages and maintenance pointsY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacY4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacEnergy saving and high efficiency: Graphite can quickly rise and fall temperatures (20℃/min), which saves more than 30% energy compared to traditional electric furnaces.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Life management: Boron-doped graphite parts can improve oxidation resistance and extend service life.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Safety protection: Double-layer water-cooled furnace shell + automatic power off at overtemperature to ensure continuous operation.Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Y4IMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Tips: Three points need to be paid attention to when selecting the model - maximum temperature requirement (such as >2000℃, choose tungsten-rhenium temperature measurement), cavity size (adaptive workpiece), atmosphere type (nitrogen/argon protection, etc.). For more technical details, please refer to industry cases. Zhengzhou Protech Technology Co., Ltd has rich experience in the thermal and new materials production fields. Welcome to consult at any time.