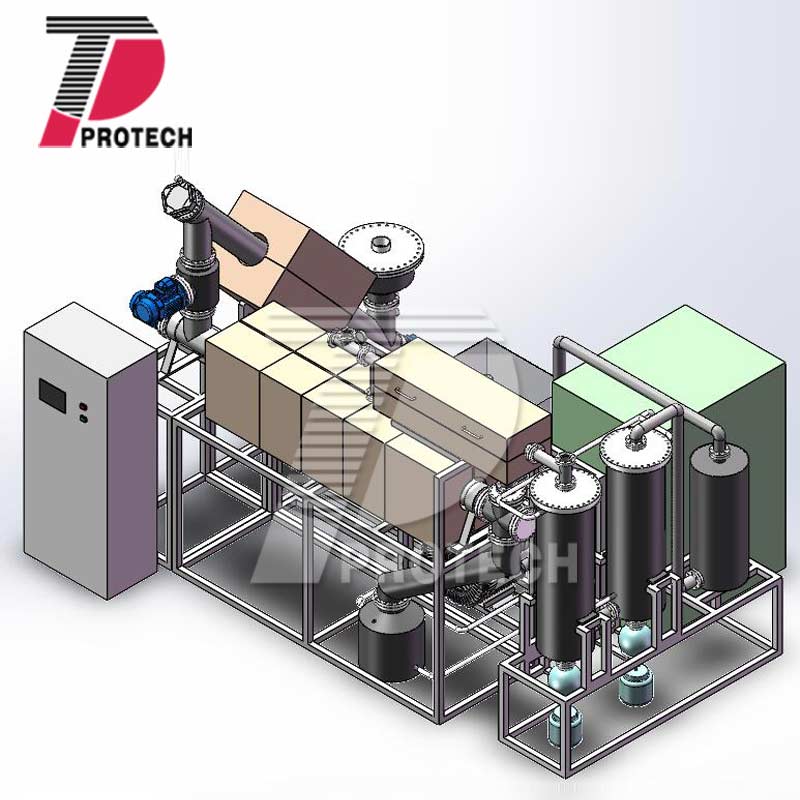

model:PT-BPU

Biomass pyrolysis unit

Application: The biomass pyrolysis unit adopts a semi-automatic assembly line method, which realizes feeding and discharging at the same time, and can collect carbon, biomass oil, etc. The tail end is equipped with an automatic ignition device, a component test interface and a gas measurement device.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Product Description:CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The biomass pyrolysis unit adopts a semi-automatic assembly line method, which realizes feeding and discharging at the same time, and can collect carbon, biomass oil, etc. The tail end is equipped with an automatic ignition device, a component test interface and a gas measurement device.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The main features:CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1. Reasonable structure design, simple operation, easy installation and maintenance.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. The stage design of drying, preheating and cracking can reduce the wear of the material and the screw at high temperature.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. Multi-temperature zone design, and the adjustable speed is more suitable for the adjustability of the process.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4. The heat preservation treatment is performed during the process; it can reduce the blockage of the pipeline due to condensation of tar, and regular high temperature treatment can clear the carbon coke in the pipeline, which is easy to maintain:

- lUsing a live connection structure, the pipe fittings can be quickly disassembled for physical cleaning.

- l Designed with sufficient power (up to 1000 degrees), the carbon coke can be re-vaporized at high temperature to achieve the effect of cleaning the furnace tube (especially for the pyrolysis carbonization section and the thermal insulation vaporization section).

- l Flexible pipe connections are used between the transfer sections, which can facilitate later replacement and function expansion.

5. The gas pipeline sealing design can realize an oxygen-free environment and reduce the function of being oxidized in the process.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

6 The furnace body is equipped with: output voltage and output current monitoring table, the heating status of the furnace is clear at a glance.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

7. With over-temperature alarm and power-off, and leakage protection functions, the operation is safe and reliable.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

If you need more information, you can contact us to customize.CxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacCxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacCxYMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac