0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

Product overview:

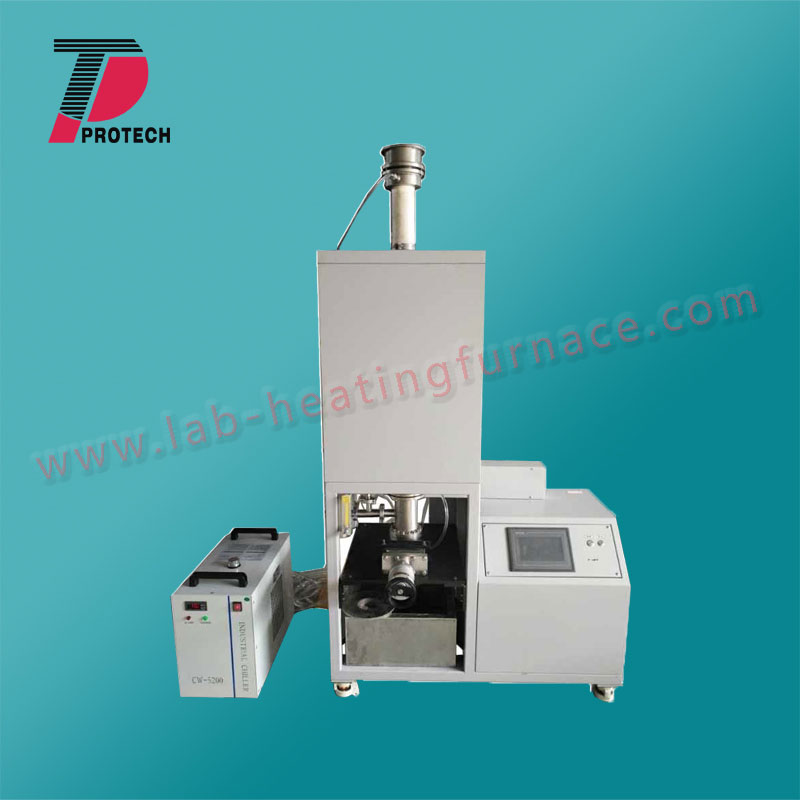

PT-T1700 vacuum tube quenching furnace uses silicon molybdenum rods as heating elements, and is equipped with a corundum tube with a diameter of 80mm and a liquid sealed container for sample quenching. The device can quickly drop samples from high temperature environments (up to 1700 degrees) into ice water or oil in liquid containers during experiments, which is very suitable for laboratory research on phase change and microstructure properties of materials.

technical parameter:

|

Furnace structure |

(1) Double-layer shell structure, and an air cooling system is installed to make the surface temperature of the shell less than 55 degrees (2) 1800 type high-purity alumina fiber is used as the furnace insulation material, and the entire insulation layer is made of all-fiber materials. (3) The instrument contains a corundum furnace tube and a set of stainless steel sealing flanges (a stainless steel needle valve and a mechanical pressure gauge have been installed on it). (4) The sealed liquid container is connected to an 80mm corundum tube through a gate valve, so that the sample falls into the liquid container without contamination. |

|

power |

Up to 7KW |

|

Input voltage |

Single phase AC220V 50Hz |

|

Long-term working temperature |

800-1600 ℃ |

|

Maximum working temperature |

1700℃ <1 hour |

|

Maximum heating Cooling rate |

The temperature rise and fall rate below 1200°C is 5°C/min; the temperature rise and fall rate above 1200°C is 10°C/min |

|

Length of heating zone |

300 mm |

|

Length of constant temperature zone |

150 mm temperature accuracy: +/- 5℃ |

|

Heating element |

6 1800 U-shaped silicon molybdenum rods |

|

Thermocouple |

Type B double platinum rhodium thermocouple |

|

Monitoring thermocouple |

Type B double platinum and rhodium thermocouple, the upper flange has an armored thermocouple hole, and the movable thermocouple position can monitor the temperature in the tube |

|

Chiller |

Model: CW5200 Power supply: 220v 50hz 0.52KW Cooling capacity: 1281Kcal/h Water tank volume: 6L Maximum lift: 10 M Water inlet and outlet: copper nozzle with 10mm outer diameter |

|

Temperature Controller |

1. Adopt PID method to adjust the temperature and set 50 steps of temperature rising and falling program 2. Temperature control accuracy +/- 1 ℃ /3 33, RS485 communication interface, PC temperature control software and interface module, temperature control program and temperature curve Line into the computer; 4. With over-temperature and broken couple protection, the heating circuit of the electric furnace is automatically cut off when the temperature is over or broken, allowing unattended operation (when the temperature of the electric furnace exceeds 1720 degrees or the thermocouple is blown, the AC relay on the main circuit will be automatically disconnected , The main circuit is disconnected, the ON light on the panel goes out, and the OFF light is on, limited protection of the electric furnace); 5. With power-off protection function, that is, when the furnace is powered on after the power is turned off, the program does not start from the initial temperature rise, but the furnace temperature starts to rise when the power is turned off; 6. The instrument has the function of temperature self-tuning; |

|

Furnace tube |

Material: Corundum tube OD: 80 mm; ID: 70mm; length 1000 mm The instrument must be plugged before use to prevent heat radiation |

|

Vacuum sealed flanges and valves |

1. A stainless steel sealing flange, hook device, ejection port and armored thermocouple pair interface are installed on the top of the furnace body; 2. A plug-in valve and a mechanical pressure gauge are installed at the bottom of the furnace body; 3. There is an air inlet on the bottom sealing flange, and an argon 6-60ml/min float flowmeter |

|

Customized part |

A 34mm round hole is reserved at the center of the upper flange for the ejection device; The symmetrical parts on both sides of the upper flange are equipped with hook devices for hanging the crucible (50*50mm), the hanging wire is molybdenum wire, and the hook device is electrically controlled, which can be controlled by PLC touch screen (provided by a third party) through the communication port; The armored structure is left on the upper flange for installing thermocouples to monitor the temperature in the tube; |

|

Quenching vessel

|

1. A stainless steel box for holding quenching liquid is fixed at the bottom of the furnace tube; 2. A large manual flapper valve is installed between the bottom of the furnace tube and the liquid box; 3. A sample hanging device that can withstand a maximum of 1500g is installed on the top of the flange; 4. Push down the hanging device to release the sample into the quenching liquid box; 5. Before releasing the sample, 5PSI of argon must be flushed and the manual insert at the bottom of the furnace tube must be opened. Plate valve |

|

trigger |

Phase shift trigger (with soft start and current limit function); Current limiting function: no matter how you adjust the heating time, the secondary current of the electric furnace after passing through the transformer is limited to less than 160A, which protects the equipment limitedly, no matter how you operate it, it will not burn the equipment; Soft start function: The current will increase slowly when starting up, and the impact on the heating element is small, which is beneficial to the extension of the life of the heating element; When the current exceeds 1.5 times of the set current, the trigger will automatically turn off to protect the circuit; |

|

The standard |

1 set of furnace body, 1 corundum tube (φ80*1000mm), 1 pair of sealing flanges, 2 type B thermocouples, 5 corundum crucibles (φ50*50mm), molybdenum wire 5 meters, 1 water cooler, stainless steel box 1 (400*400*200mm), 4 pipe plugs, 8 flange seals, 1 pair of high temperature gloves, 1 crucible hook, 1 manual, 1 certificate |