model:

SIC heating elements.

Application: Model: customized according to user needs

Uses: widely used in the research, production and manufacturing of metallurgy, steelmaking, glass, ceramics, refractory materials, crystals, electronic components, semiconductor materials, etc.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Description: BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

silicon carbide heating elements(SiC heating element) is one type of ceramic heating elements, which use six-party high purity green SiC powder as the main raw material. Silicon is recrystallized less than 2200 ℃ high temperature to form finished materials. The using temperatures up to 1450 °C under oxidation atmosphere, and constant working life up to 2000 hours. It is widely used in various high temperature electric furnaces and other electric heating devices, such as in the industries of magnet, ceramics, powder metallurgy, glass, metallurgy and machinery etc.BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Advantage:BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1.Selecting high purity green SiC powder, to ensure best foundation for top quality.BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2.SiC tube is extruded by 500T press machine, to ensure high density uniform through whole length.BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.Excellent resistance rate between heat zone and cold zone, to avoid over-temperature of cold zone to damage furnace body.BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.Special technology to spread a protect film on the surface of hot zone, which enhance the Antioxidant property evidently and lengthen the service life.BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Category :

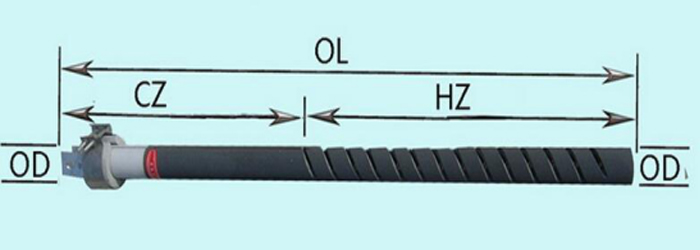

1,GC type Sic heating element.

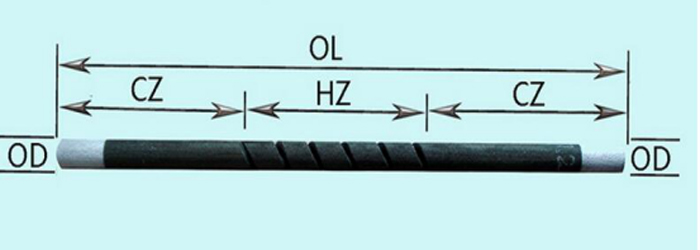

2.GD type Sic heating element.

3.SD type Sic heating element.

4.SG type Sic heating element.

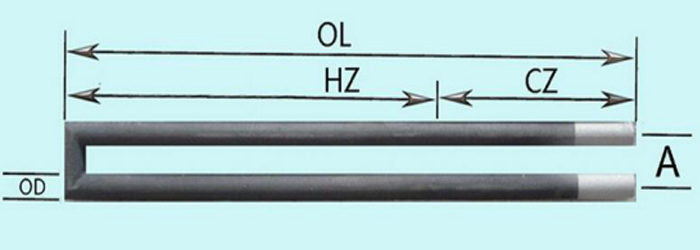

5.U Type Sic heating element.

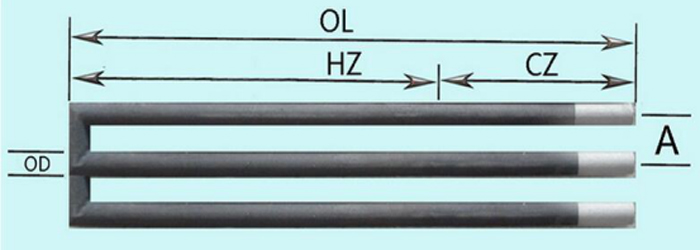

6.W Type Sic heating element.

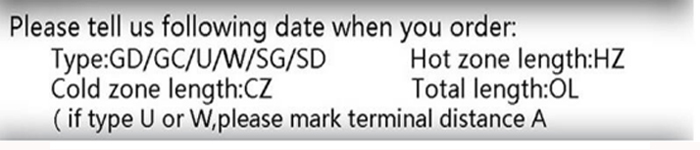

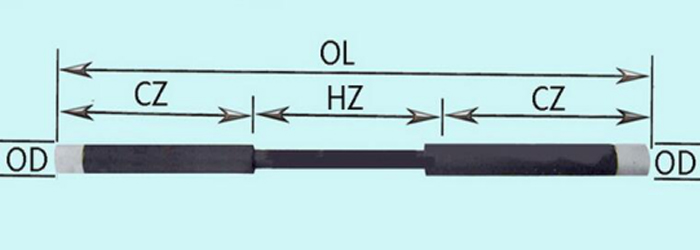

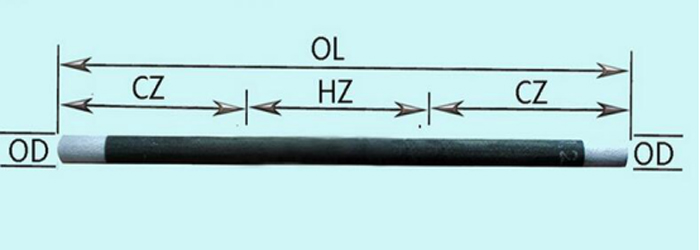

How to Order SiC heating elementBukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1. Choose the shape you need, like Rod, U, W, Single Spiral etc.BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. Out Diameter (OD)BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. Heating Zone Lengh (HZ)BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4. Overall Length (OL)BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5. Resistance you need.BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Aplication case:

Package:

BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

BukMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac