Specific Introduction:

PT 1400 ℃ high-temperature atmosphere furnace PT-A1400-216LY uses silicon carbon rods as heating elements, which can achieve rapid heating; The furnace body adopts a double-layer furnace shell structure, equipped with an air cooling system, and the surface temperature of the furnace shell is below 60 ℃; The furnace door and roof are sealed with high-temperature silicone rubber, which can be pre vacuumed or a protective atmosphere can be introduced; Adopting double-layer ceramic fiber board, energy-saving and environmentally friendly. PT-A1400-216LY atmosphere tube furnace belongs to a type of atmosphere furnace.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

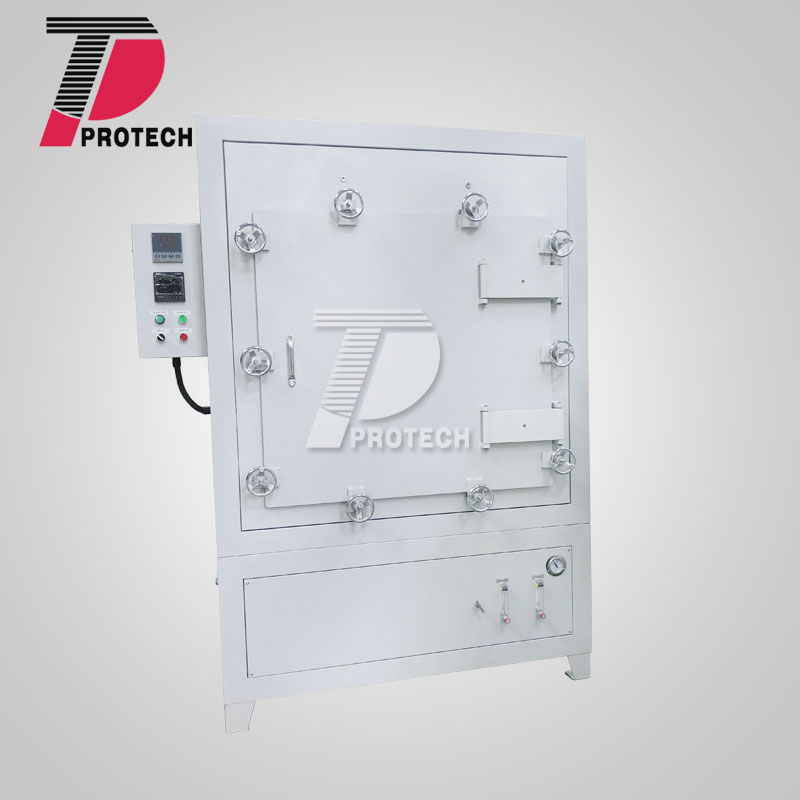

Actual photo of PT 1400 ℃ high-temperature atmosphere furnace8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacApplication:

PT 1400 ℃ high-temperature atmosphere furnace is suitable for high temperature sintering, metal annealing, new material development, organic matter ashing, quality testing, and small batch production in universities, research institutes, and industrial and mining enterprises.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacProduct advantages:

1.The heating elements are evenly arranged on multiple surfaces to ensure uniform heating during operation.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2.Using silicon carbon rods as heating elements, the furnace body adopts a double-layer furnace shell structure and a double-layer air cooling system, which can quickly raise and lower the temperature, and the surface temperature of the furnace shell is low;8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.It has sealing properties and is equipped with a vacuum pump to pre pump and replace gas.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.There are inlet and outlet ports for air intake and exhaust according to process requirements.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5.Built in PID Auto-Tune function, with overheat and thermocouple disconnection protection, overheat protection and alarm allow unattended operation.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

6.The electric furnace temperature control system adopts artificial intelligence adjustment technology, which has PID adjustment, fuzzy control, Self-tuning capabilities and can prepare various temperature rise programs. The temperature display accuracy of the control system is 0.5 ℃, the temperature field stability is ± 5 ℃, and the temperature rise rate can be arbitrarily set at 1~20 ℃.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

7.30 programmable segments for precise control.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8.Optional digital vacuum gauge can display the vacuum level in the furnace in real-time.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacTechnical parameters:

| PT 1400 ℃ High Temperature Atmosphere Furnace |

| Product model |

PT-A1400-216LY |

| Furnace Structure |

Carbon steel outside shell with cooling fans8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

temperature of furnace shell below 60deg.C.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Carbon steel air-tight tank with three valves for vacuum pump, inlet tube, outlet tube.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Two layers of ceramic fiber insulation materials8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

First layer: 1600deg.C ceramic fiber board8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Second layer: 1400deg.C ceramic fiber board |

| Chamber dimension |

600*600*600mm |

| Max. temperature |

1400℃ |

| Working temp. |

≤1300℃ |

| Heating rate |

0-20℃/min (Suggestion: 0-10℃/min) |

| Temp. Control accuracy |

0.5℃ |

| Thermocouple |

S-type thermocouple |

| Temp. control |

PID automatic control via SCR (Silicon controlled rectifier)8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Power control with phase angle fired, current limiting resistor8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

30 programmable segments for precise control8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Bulit-in PID auto-tuned function with overheating & broken thermocouple broken protection.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Over temperature protection and alarm allows for operation without attendant |

| Heating element |

SiC heating rods one the two sides of the heating chamber.8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

| Working voltage |

220V, 50Hz, Three phases(Customized) |

| Power |

60kW |

| Warranty Period |

1 year (Consumable uncovered.) |

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Actual photo of PT 1400 ℃ high-temperature atmosphere furnace8pnMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac