| Chamber Structure |

Side Door |

| Display |

LED Display |

| Max. Temperature |

1700℃ for short time |

| Continuous working Temperature |

≤1600℃ |

| Heating Rate |

Suggestion 0~10℃/min (Max.20℃/min) |

| Inside Chamber Size |

600*600*600mm (Width * height * depth) |

| Heating Element |

MoSi2 |

| Thermocouple |

B Type |

| Max. Power |

60Kw |

bQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Working Voltage |

AC 380V,3 phases, 50 Hz |

| Temperature Control |

PID automatic control via SCR power control |

| Heating curves |

30 steps programmable |

| Chamber material |

Alumina Fiber |

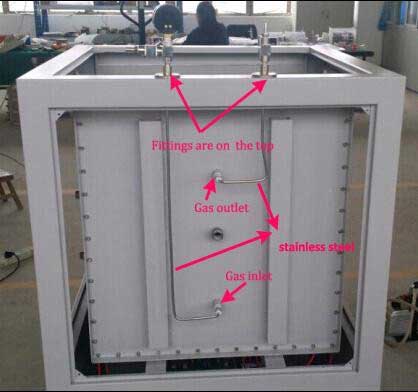

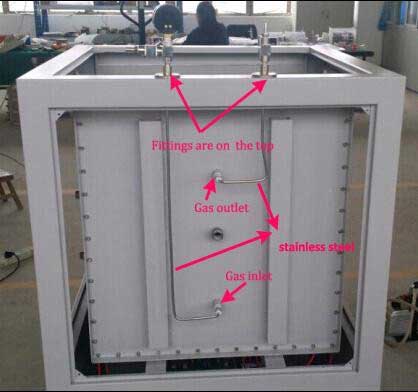

| Gas inlet and outlet |

Stainless steel gas inlet with needle valvebQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Stainless steel gas out let with needle valve and mechanical pressure gaugebQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

| Hand Wheel |

To tight the door for better sealing in chamber. |

| Float Flow meter |

Standard flow range:bQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

FFC1: 10-100ml/minbQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

FFC2: 16-160ml/minbQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Or according to your requirement. |

| Atmosphere Condition like nitrogen , argon |

YesbQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The furnace max working temperature up to 1500℃if inlet nitrogenbQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The furnace max working temperature up to 1600℃ if inlet argon |

| Warranty |

One year warranty (Consumable parts such as heatingbQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

elements are not covered by the warranty) |

| Standard Accessories |

Crucible tong x 1 pairbQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Protective glove x 1 pair |

| External Dimensions reference |

1200*2100*1250mm (width* height*depth) for 600*600*600 inside chamber size.bQXMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Note: if the external dimensions is too big for you , we could design and produce the furnace part and control parts separately, please check the last picture on last page as reference) |