model:

Fluidized bed-powder carbon nanotube growth equipment

Application: Application: Graphene growth, carbon nanotube development, silicon nitride film deposition, two-dimensional material growth, crystal material battery electrode field.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Main features:

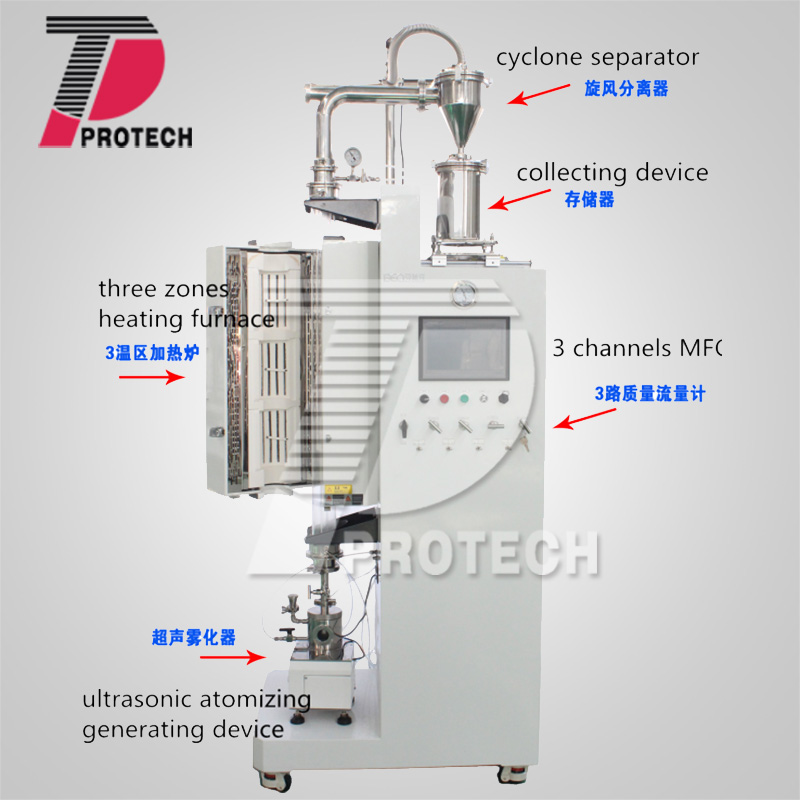

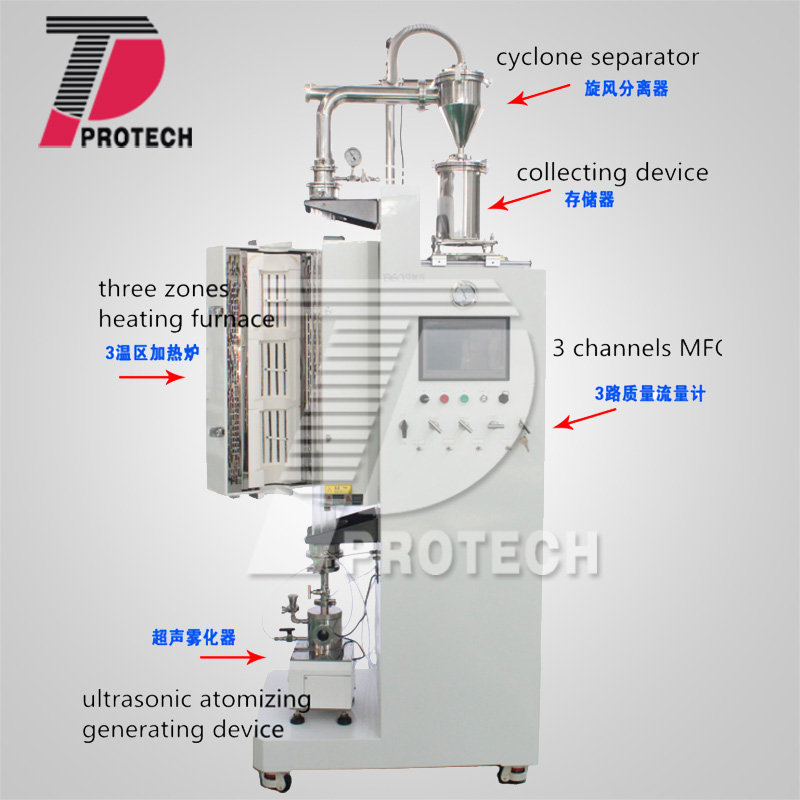

Ø fluidized bed consists of Automatic liquid adding device,ultrasonic atomizing generating device, gas supply device, gas flow control device, three-temperature zone fluidized bed reactor and heating device, cyclone separator, solid collecting device, and purification processing device.

Ø Outlet of the gas supply device is connected with the inlet of the ultrasonic atomizing device after passing through the gas flow control device, and the liquid outlet of the automatic liquid adding device is connected with the liquid inlet of the ultrasonic atomizing device. The outlet of the ultrasonic atomizing device is connected with the inlet of the fluidized bed reactor of the three-temperature zone, and the discharge port of the reactor is connected to the cyclone through a transparent pipe, and the gas outlet above the cyclone separator is connected with the purification treatment device, the lower solid collection outlet is connected with the solids collector. After passing through the cyclone, a large amount of gas is passed up through the purification device to the atmosphere, and the solids are trapped in the solids collection device.

Ø The most difficult thing to control the growth of carbon nanotubes is the interaction between the gas field and the temperature of the flow field. Because there are too many variables,can not ensure consistent form carbon nanotubes, and the quality is very low. Our equipment completely solves the gas field and flow field and The interaction of temperature variables.

Ø The solution uniformly mixes the gas through the flow meter and the static mixing chamber, and through the upper ventilation, the gas passes through the double tube ( sandwich tube preheats gas, while inner chamber grows carbon nanotubes ) to ensure the temperature of the introduced gas into the growth chamber. Solving problem of uniform air intake through the structural design of the porous ceramic mesh. The growth field of the growth chamber is stabilized to ensure high quality and repeatable carbon nanotubes.

Technical Parameters:

|

Furnace |

|

Max. Temp |

1200°C |

|

zone length |

Heating:200+200+200mm

Constant:400mm |

Temperature Controller

|

l PID automatic control and auto-tune function.

l 30 programmable segments for precise thermal processing.

l Built-in protection for the over-heated and broken thermocouple.

l Operation interface is 10 “ touch screen

|

Heating Elements

|

· Resistance wire, Fe-Cr-Al Alloy doped by Mo

|

Temperature Accuracy

|

+/- 1 °C |

Processing tube

|

Material:high purity quartz

Size:outer 80mm, inner 50mm |

|

Gas supply system |

|

Connector style |

Double cutting ferrule stainless steel connector |

|

Standard range(N2) |

50sccm、100sccm、200sccm、500sccm; optional |

|

Accuracy |

±1.5%FS |

|

Response time |

Gas characteristics:1~4sec

Electrical characteristics:10sec |

|

Linearity |

±0.5~1.5% |

Working pressure difference range

|

0.1~0.5MPa |

|

Max. pressure |

3MPa |

|

Pressure vacuum gauge |

-0.1~0.15 MPa, 0.01 MPa/grid |

|

Vacuum unit |

|

pumping |

63m³/h |

|

Oil capacity |

2L |

|

Rotation rate |

1440rpm |