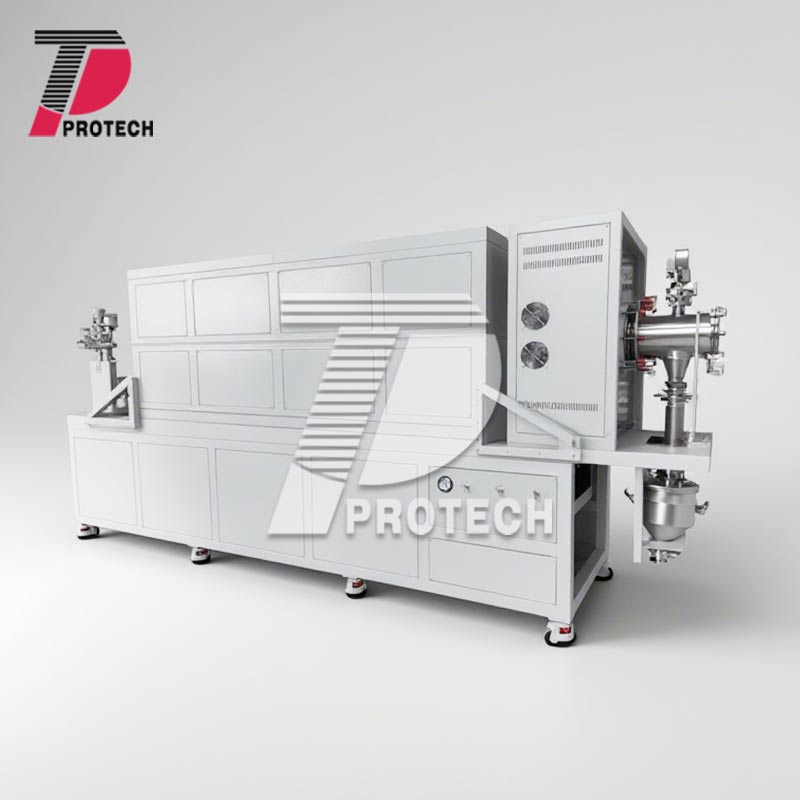

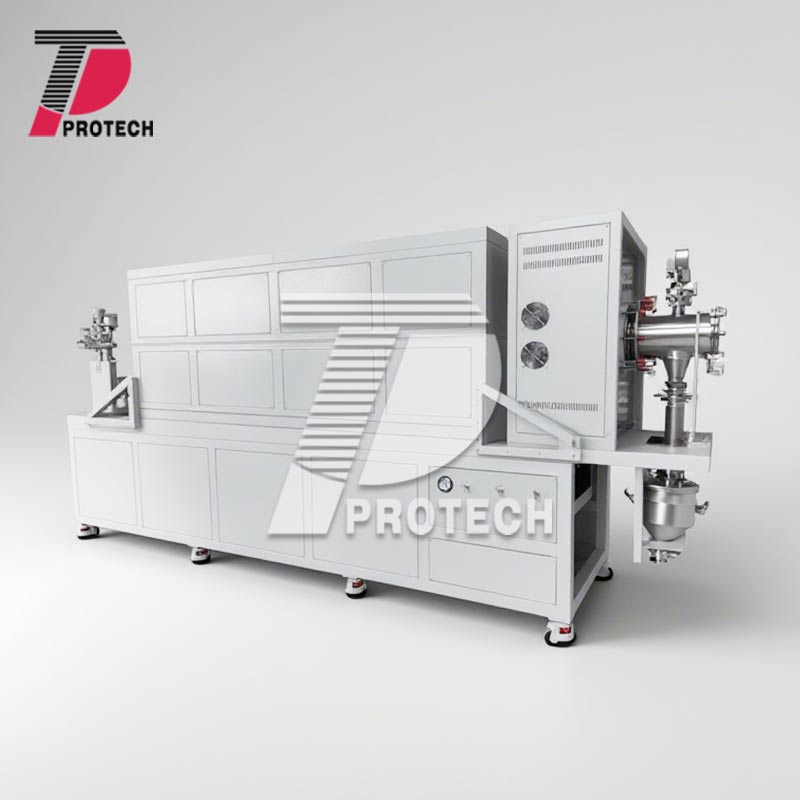

model:PT-TX1100-S120-240-120LK3W

Batch Rotary Tube Furnace

Application: The furnace's quartz tube construction ensures contamination-free processing, while its multi-zone heating design guarantees consistent temperature profiles across the 2000mm length.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Product IntroductionnahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacThis system combines precision control with operational safety, making it the ideal choice for demanding material processing tasks. The furnace's quartz tube construction ensures contamination-free processing, while its multi-zone heating design guarantees consistent temperature profiles across the 2000mm length. With a maximum temperature of 1100°C and programmable heating rates, it accommodates a diverse array of thermal treatments. The intuitive touchscreen interface and remote IoT functionality simplify operation, while integrated safety features like gas leak alarms and mechanical seals provide peace of mind. The durable 316L stainless steel receiving bin completes the system, offering reliable material collection.nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacnahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacApplicationsnahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacEngineered for versatility, this furnace excels in the following key areas:nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Catalysis Science: Facilitating the synthesis and activation of high-performance catalysts.nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Advanced Materials: Enabling the production of ceramics, composites, and nanomaterials through precise thermal processing.nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Chemical Processing: Supporting controlled atmosphere reactions, including those involving nitrogen and sulfur dioxide.nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Quality Control: Providing a reliable platform for material annealing, sintering, and purity testing in R&D and production environments.nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacnahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

nahMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

| Product Name |

Intermittent rotary tube furnace |

| Product Model |

PT -TX1100-S120-240-120LK3W |

| highest temperature |

1100°C, operating temperature ≤1000°C |

| control system instrument |

10-inch touchscreen |

| Furnace tube |

Quartz, outer diameter 120-240-120mm |

| Box color |

Standard color |

| heating zone |

2000mm (length)4 temperature zones 500*4 |

| heating element |

External resistance wire |

| Sealed structure |

Mechanical seals at the inlet and outlet ends |

| mass flow meter |

2-way (nitrogen, sulfur dioxide) |

| Mixing tank |

1 set |

| heating rate |

0-10°/min |

| power distribution cabinet |

Independent power distribution cabinet |

| pressure gauge |

Mechanical pressure gauge + digital pressure gauge |

| hot electricity even |

Type N, 4 temperature controllers + 1 Type N armored coupler |

| Environmental alarm |

2 sets (sulfur dioxide, hydrogen sulfide) |

| Furnace tube speed |

Adjustable from 3-6 r/min |

| tilt angle |

0-17 ° adjustable |

| Rotational structure |

chain |

| Feed structure |

Manual feeding |

| receiving bin |

Material: 316L, 10L |

| Electrical control system |

With IoT functionality, it enables remote control of intake volume, temperature, speed, and tilt angle within a certain distance. |

| Chain function |

Gas leak alarm - close the intake valve - open the exhaust valve |

| intake |

1-way manual air inlet needle valve (air inlet at the discharge end) |

| exhaust |

2-way manual exhaust valve + 1-way electric ball valve |