0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

The main raw material of this project is clean waste tires purchased from outside. There is no need for pre-processing processes such as cleaning, crushing, and wire drawing. The whole tire automatically enters the cracking furnace directly under the action of the automatic feeder (retractable and mobile). The feeding process high degree of automation, safe, convenient, time-saving and labor-saving.

With the rapid development of the automobile industry and transportation industry, there are more and more waste tires, forming black garbage and causing black pollution. Waste tires are recycled and comprehensively utilized, and their products and extended products are regarded as important renewable resources. Recycling and processing of rubber products such as waste tires is an important way to turn waste into treasure, turn harm into benefit, eliminate environmental pollution caused by waste rubber, and protect the environment.

10KG Lab Scale Pyrolysis Unit

Technical Parameters:

| Part I - Reactor Part |

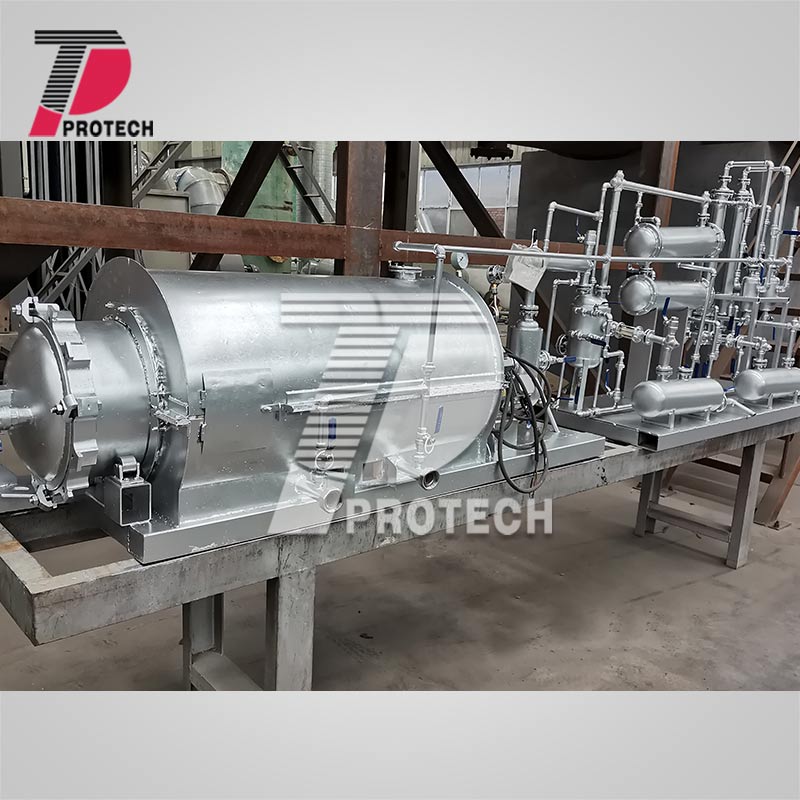

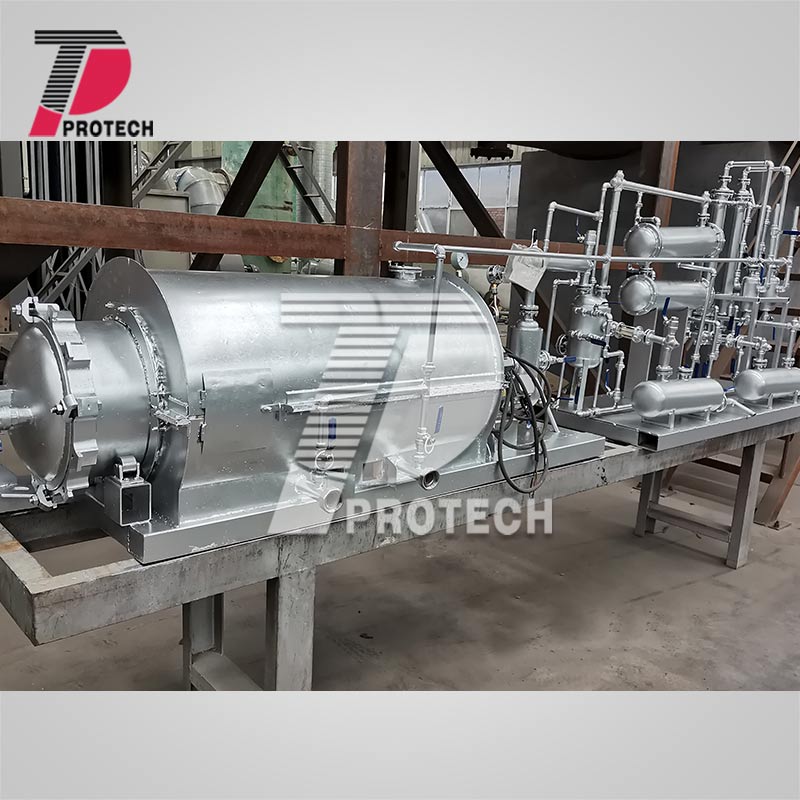

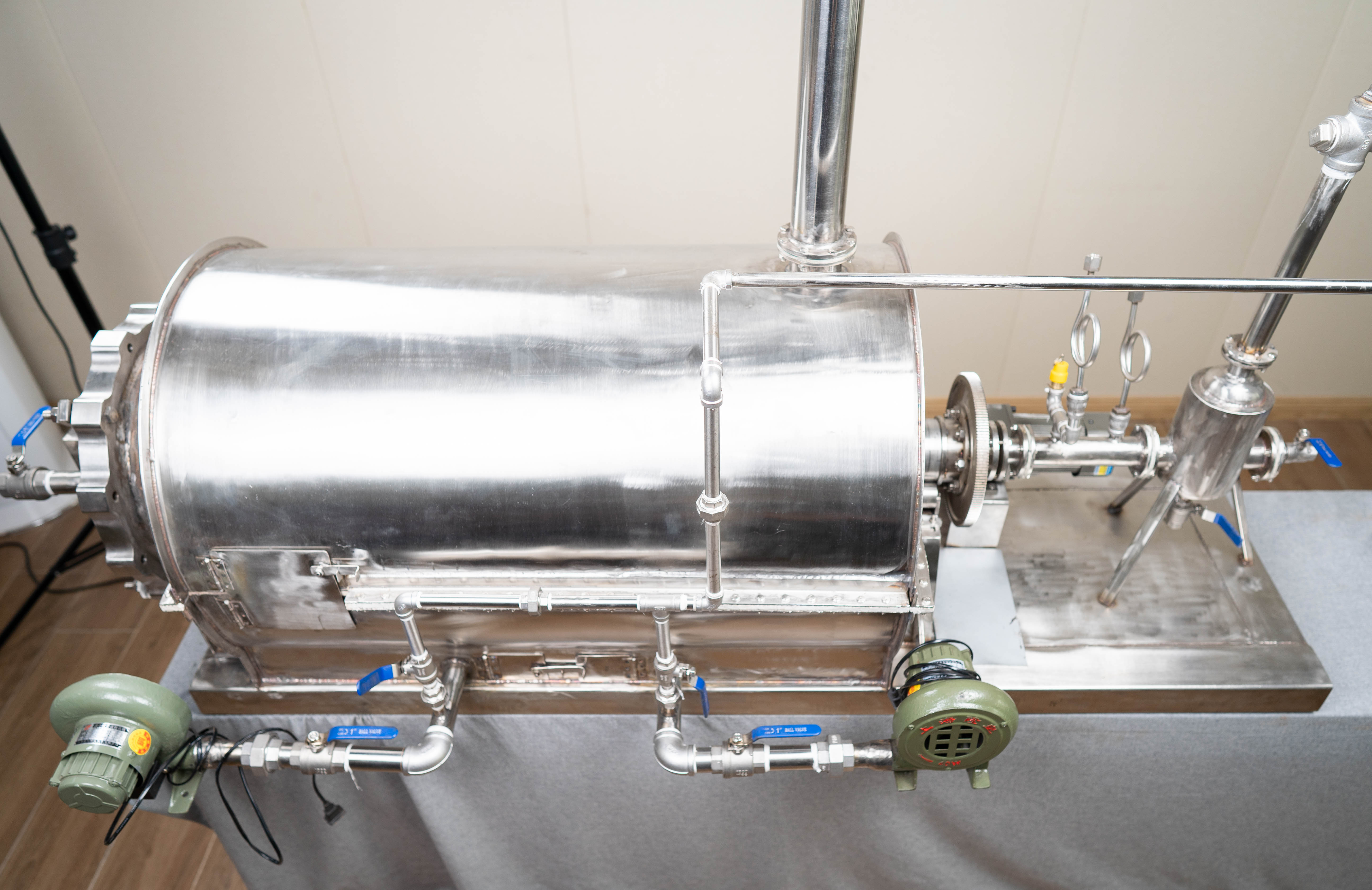

It including the reactor vessel, insulation, motors, reducer, chimney, furnace,etc. Similiar as howing in the picture below.

|

| Part II - Cooling System |

It includes the catalyst chamber, top cooling pipes, oil-water separator, condensers,oil tanks, anti-back fire devices, connection pipes and joints etc.

|

| Item | Description |

| Reactor (finished installation one) | 5~10kg capacity,Q345R boiler plate with motor reducer, furnace, chimney |

| Cooling System (all the parts finished installation before delivery in seller’s factory) | catalyst chamber, top cooling pipes, oil-water separator, 2 sets of horizontal condensers,2pcs oil tanks, 2pcs anti-back fire devices, connection pipes and joints etc. |

| Connected pipes | 3pcs, 10mm diameter pipes |

| Air blower | 2pcs, 40W |

| Graphite packing | 4*4 5pcs |

| Loading port flange | 1pcs |

| Carbon black discharging flange | 1pcs |

| Wrench for unloading the flange of cb | 1pcs |

| Ball valve | 3pcs |

| Bending | 5pcs |

| Pipe joints | 3pcs |

| Nipple | 3pcs |

| Screw | 50 units M6*25 |

| Thermal couple | 1pcs |

| Pressure gauge | 2pcs |

| Ring | 1pcs |

| Temperature controller | 1pcs |

| Sealing material | 5 boxes |

| Bend table | 1pcs |

| Safety valve | 2pcs |

| Valves | 2pcs |

| Dimension | 3.8*0.6*1.2m |

| Weight | Approx. 500kg |

| PP(microwave oven food box/yogurt bottles,etc.) | 50%~75% |

| PE (Plastic film / plastic wrap) | 50%~75% |

| PS (fast food boxes / instant noodle boxes) | 50%~75% |

| ABS (Engineering plastics) | 40% |

| Leftovers of paper | Wet 15~20% , Dry 60% |

| House garbage | 35-50% |

| Plastic cable | 80% |

| Plastic bags | 50% |

| Submarine cable | 75% |

| Rubber cable | 35% |

| Soles | 30% |

| Big tires | 45%~50% |

| Small tires | 35%~40% |

| PVC (raincoat/building materials.etc.) | Not applicable |

| PET (mineral water bottles/sodas beverage bottles) | Not applicable |

Final Products and Application:

| Products | Application |

| 45%~50% Pyrolysis oil (Tire oil/Plastic oil) |

|

| 25%~30% Carbon black |

|

| 15%~20% Steel wire | Sell it into iron and steel factory directly |

| 5%~10% Waste gas | Recycle it into furnace as fuel for heating the reactor |