Specific Introduction:

The working temperature of the 1200 ℃ CVD chemical vapor deposition coating system is from 300 ℃ to 1200 ℃, equipped with a vacuum pump and gas mixing device. It adopts a temperature control system with high temperature accuracy, excellent gas flow accuracy, easy operation, and excellent insulation effect and temperature uniformity. Click to view more CVD System.E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

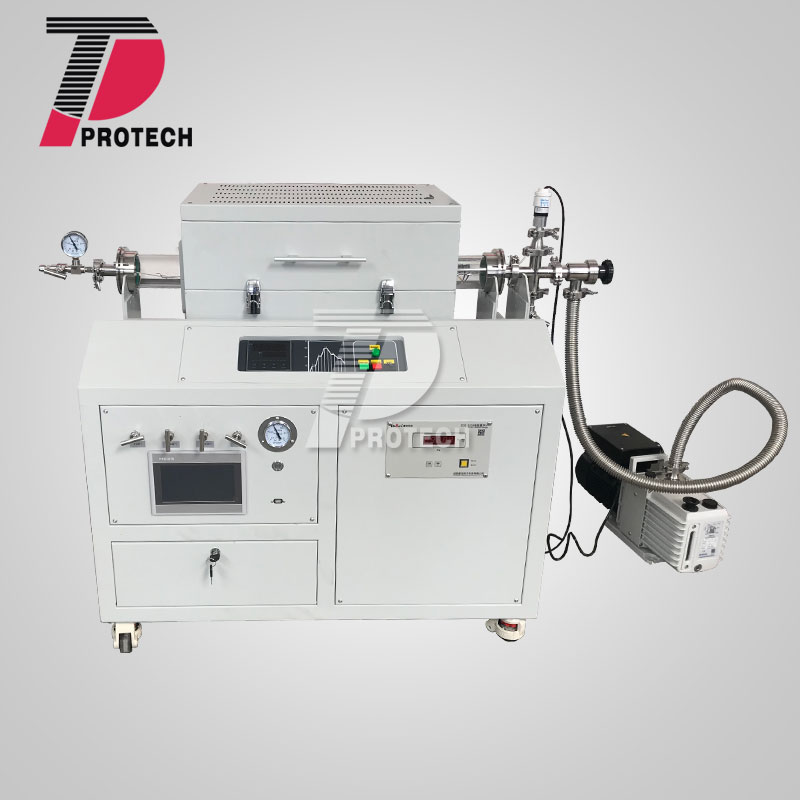

Real shot of 1200 ℃ CVD Chemical Vapor Deposition Coating SystemE8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Application:

The 1200 ℃ CVD chemical vapor deposition coating system is suitable for CVD processes, such as silicon carbide coating, ceramic substrate conductivity testing, controllable growth of ZnO nanostructures, ceramic capacitor (MLCC) atmosphere sintering, and other experiments. Mainly used for experiments and production related to vapor deposition in universities, research centers, and production enterprises.E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Technical parameters:

| Product name |

Chemical vapor deposition system |

| Model |

PT-TCVD1200-S80LK1 |

| High temperature tube furnace |

| Hearth mode |

open type |

| display mode |

LED |

| Chamber material |

Alumina refractory fiber |

| Heating element |

Alloy heating wire |

| Max.temperature |

1200℃ |

| Working temperature |

≤1100℃ |

| Heating rate |

0-10℃/min |

| Heating zone |

Single zone |

| Temperature zone length |

440mm |

| Furnace tube material |

High purity quartz |

| Furnace tube outer diameter |

80mm |

| The length of the furnace tube is approx. |

1000mm(Subject to actual supply) |

| Sealing method |

Removable stainless steel sealing flange. Easy to disassemble and assemble, good sealing |

| control mode |

Intelligent PID control with multi-stage programmable temperature control and self-tuning function |

| Temperature curve |

Multiple "time-temperature curves" can be set arbitrarily |

| Call the police |

With overtemperature and disconnection alarm |

| Temperature measuring element |

K type thermocouple |

| Power supply |

220V 50Hz |

| Heating power approx. |

4KW |

| Air supply system |

| flow meter |

Three-way mass flow meter (range can be selected according to needs) |

| A way range nitrogen |

0~1000SCCM |

| B road range methane |

0~500SCCM |

| C Road Range Ethylene |

0~500SCCM |

| Mixed air |

Contains a precision air mixing tank |

| Power supply |

220V 50HZ |

| Working temperature |

5℃-45℃ |

| Vacuum system (including stainless steel bellows and related connection accessories) |

| Vacuum pump pumping speed |

2L/S pumping speed mechanical rotary vane pump, bellows and related connectors, ultimate vacuum can achieve 10pa |

| Digital vacuum gauge |

Digital resistance vacuum gauge integrated into the movable air supply system box |

| Regulation of use |

resistance gauge |

| Measuring range |

1.0×105—1.0×10-1 (Pa) |

| measurement accuracy |

±10% |

| zero drift |

±2% |

| Number of measurement channels |

1 channel |

| Display the number of channels |

1 window |

| Display method |

Five-digit LED digital display, using scientific notation, for example: 1.2E-1, expressed as 1.2×10-1Pa |

| power supply |

AC/220V/50Hz/15W |

| The overall dimensions of the whole machine are approx. |

Including vacuum pump, width 1000*depth 600mm*height 1000mm |

| After-sales service |

●Warranty period: 15 months after leaving the factory or 12 months after acceptance, whichever comes first (excluding consumable parts such as silicon molybdenum rods, silicon carbon rods, resistance wires and man-made damage), lifetime warranty, free technical guidance on installation and Equipment debugging services. When the warranty expires, renewal services will be provided.E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

● General faults will be resolved within 24 hours, and major faults will be resolved within 72 hours. In special circumstances, technicians can go to the site to deal with the problem. |

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Real shot of 1200 ℃ CVD Chemical Vapor Deposition Coating SystemE8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

E8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Real shot of 1200 ℃ CVD Chemical Vapor Deposition Coating SystemE8BMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac